Iron frying pan recognized by the world as a town factory

Fujita Kinzoku Co.

The original iron frying pans produced by the integrated production system of a local factory have spread through social networking services and are now popular products all over the world. We visited the manufacturing site of Fujita Metal Co., Ltd. which continues to produce sellable metal products while flexibly responding to the changing times.

Solving Steel Challenges with Technology

The popularity of Fujita Metal's iron frying pans continues to grow, driven by the demand for staying homes and the camping boom. Original products such as "Frying Pan Story," which offers original products from 1,040 combinations of materials and sizes, collaborative products with apparel makers, and "Frying Pan Jew," which can be used as a plate by removing the handle, jointly developed with a design company, have become the talk of the town on social networking sites.

The reason for their popularity is ease of use. Although it is known that iron frying pans have excellent heat conduction and can be used longer than fluoroplastic-coated aluminum pans, they have tended to be avoided because they are "heavy," "rust easily," and "burn easily. Fujita Metal has solved these disadvantages with its processing technology accumulated over 70 years.

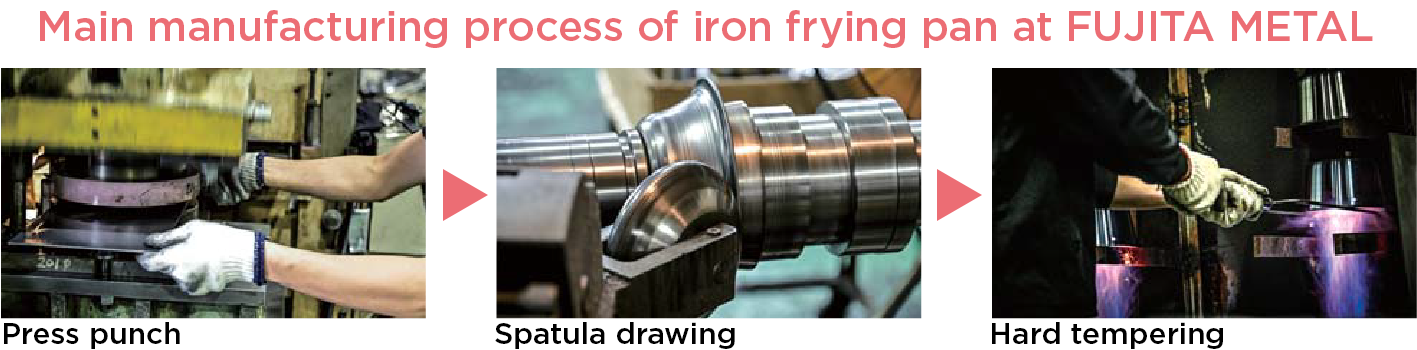

Fourth-generation president Seiichiro Fujita says, "Pressing can be mass-produced. Pressing can be used for mass production, but we use a spatula drawing process for the sides. Since it is thinner than usual, the overall weight can be reduced by 20%.

Rust and scorch" have been solved by manufacturing iron frying pans that have been blended with oil from the start. Ordinary iron frying pans are coated with a rust-proof coating, so they need to be air-baked and oiled before use. However, Induction Heating and recent gas stoves are controlled to prevent overheating during the emptying process, and many people have voiced their concerns that the coating cannot be removed. Therefore, Fujita Metal manufactures iron frying pans that can be used immediately by users by applying the hard tempering process, which involves baking the pan over a burner, soaking it in olive oil, and allowing it to dry. We are open about this processing method, but few other companies do it. Maybe it's because our company is very proactive," he says.

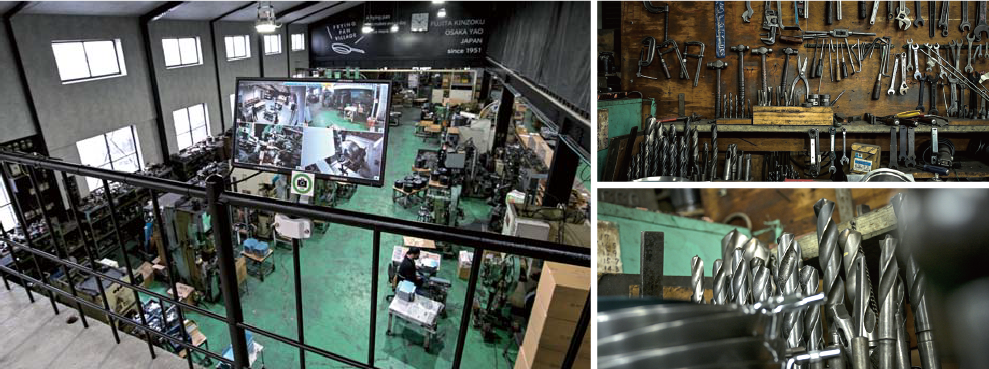

In addition, our conscientious prices are also well-received. We are able to keep prices low because of our integrated production system. Our founder's grandfather was particular about the fact that we manufacture our own molds. My father inherited my grandfather's mold manufacturing technology, and now my younger brother has taken over. The strength of the family-run factory is fully demonstrated.

Breaking free from assumptions

About 10 years ago, however, "we were on the brink of closing the company," says President Fujita. At that time, most of our customers were mass retailers and hardware stores, where pricing was strictly regulated, and when we developed products that sold well, they were quickly imitated by foreign manufacturers. We were unable to create hit products, and we were continually losing money due to foreign products.

Therefore, the company exhibited at the Tokyo International Gift Show with the aim of developing new sales channels. Although sales recovered as a result of developing new sales outlets in gift catalogs and web media, a price war ensued. Feeling uncomfortable with the price war, we launched "Frying Pan Story" as a new strategy to capture B-to-C demand on the Web.

Until then, I was under the impression that we had to deliver our products to real stores. I realized that we could connect directly with buyers via the Web and deliver products to them, and I thought this strategy would enable us to keep prices low. However, there was an unexpected voice from the production floor. We can't afford to customize one product at a time," they said. We changed our focus to original corporate products that could be produced in large lots, and we were able to get "Frying Pan Story" off the ground.

Fighting the World with Small Businesses

It was 11 years ago that we revived the iron frying pan, which had been discontinued for many years due to being pushed aside in favor of fluorinated aluminum. Shipments in the first year totaled 4,400 units, but by 2021, the company had shipped more than 160,000 units. However, President Fujita is calm: "Thanks to the boom, we have to consider these numbers as figures that will not be there in the future. Therefore, as a new business pillar, he has started to develop highly designed gardening and interior goods based on the concept of "metal that makes everyday life more enjoyable," which is already a hot topic on social networking sites. The company's highly original manufacturing has also won awards both in Japan and abroad.

The majority of our sales are still B-to-B, but we want to strengthen our B-to-C business, which has higher profit margins, because we have no advertising costs because of our social networking services.

The flexibility of the company to read the times and quickly create creative products that meet consumer needs is admirable. I think it is important to have a strong product line. If you make a half-baked product, you will be immediately noticed on social networking sites, but if you make a "real product," customers will naturally spread the word.

The "Never Overtime" site is a small, elite group of 17 people. I don't want to exceed 20 people," he says. I want to test how far we can go as a small business to compete with the rest of the world. President Fujita's passionate challenge continues.

Fujita Kinzoku Co.

Manufacture and sale of aluminum and steel household goods and hardware

Head Office:

3-8 Nishi-Yumigae, Yao City, Osaka Prefecture

Established:

1951

TEL. 072-949-3221

http://www.fujita-kinzoku.jp/

This article was published in 2022.