AC4010K / AC4015K / AC4125K

From Ultra-high-speed Machining of Gray Cast Iron to Heavy Interrupted Machining of High-strength Ductile Cast Iron

recommended Work Material

- K

Feature

From Ultra-high-speed Machining of Gray Cast Iron to Heavy Interrupted Machining of High-strength Ductile Cast Iron

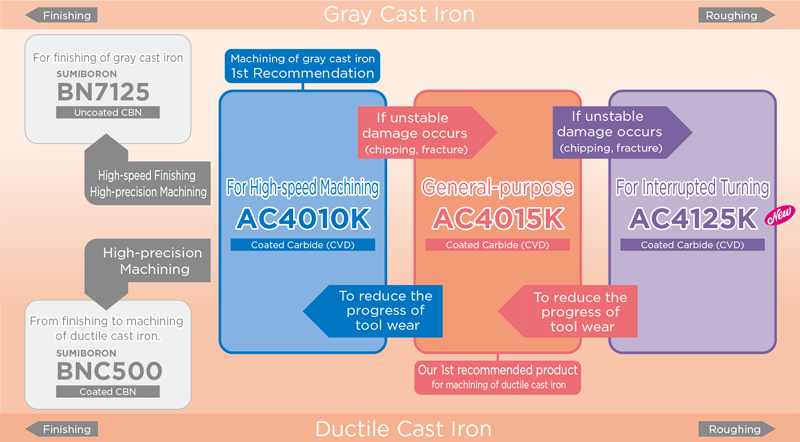

Features of AC4010K / AC4015K

Technologies for high-adhesion, crystal orientation control and residual stress control realise stable tool life for various types of cast iron, from grey cast iron (FC) to high-strength ductile cast iron (FCD).

AC4010K Our 1st recommended grade for machining gray cast iron. Ultra-thick film coating enables ultra-high-speed machining at vc=700m/min.

AC4015K Our 1st recommended grade for machining of ductile cast iron. High-adhesion and high-strength coating enables stable and long tool life.

Features of AC4125K

Excellent chipping resistance is demonstrated by the evolution of high adhesion technology, fine crystal orientation control technology and residual stress control technology, and very stable machining is realized in heavy interrupted machining and unstable machining of cast iron. In addition, it adopts a gold color that makes used corners easily identifiable.

AC4125K Our 1st recommended grade for interrupted machining of cast iron. Especially effective for stable long life in roughing of parts like differential cases and carriers.

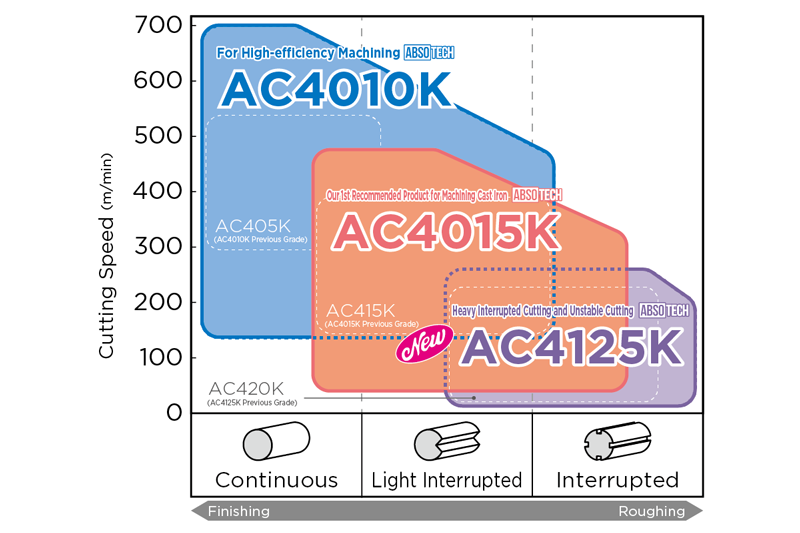

Application Range

Applications of AC4000K Series (Example)

Product Inquiry

Feel free to contact us for cutting and machining information

on cutting troubles and review of tooling as well as questions,

feedbacks, and requests for our home page.

Recommend

-

New Generation of Coated Carbide Grades for Milling

New Generation of Coated Carbide Grades for Milling- P

- K

- 焼

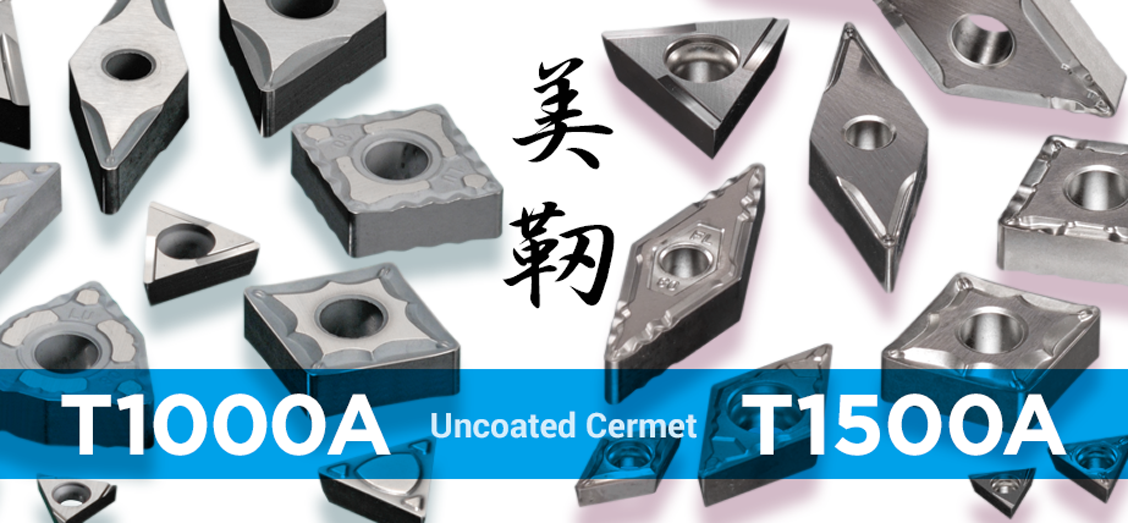

T1000A / T1500AMore Detail -

Coating Grades for Steel Turning

Coating Grades for Steel Turning- P

AC8015P / AC8020P / AC8025P / AC8035PMore Detail -

Coated Grades for Exotic Alloys

Coated Grades for Exotic Alloys- P

- M

- K

- S

- H

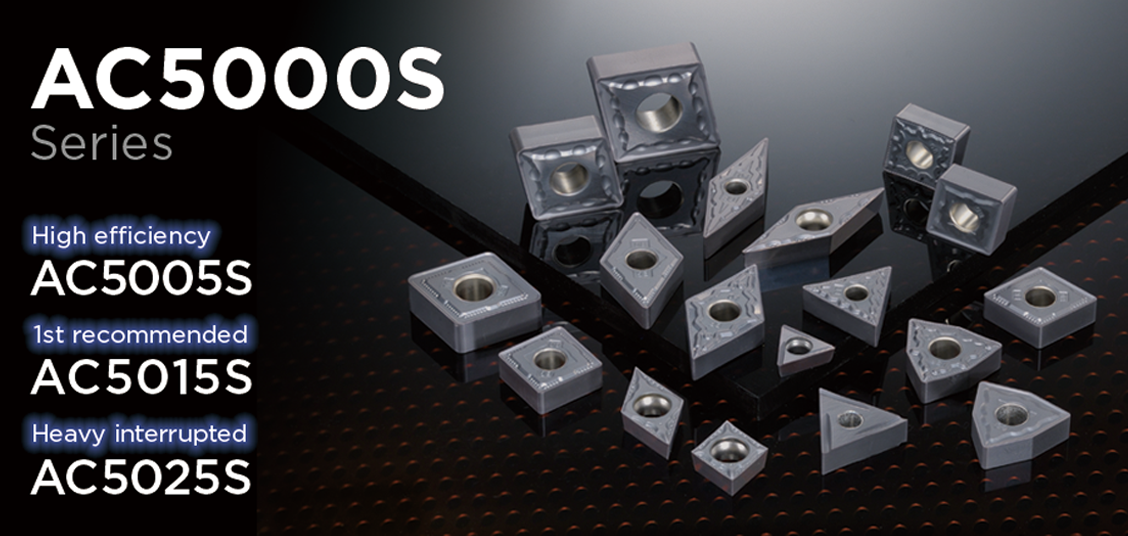

AC5005S / AC5015S / AC5025SMore Detail