Sumitomo Electric Industries, Ltd. (headquarters: Chuo-ku, Osaka, President: Osamu Inoue, hereafter "our company") employs sensing tools (cutting tools equipped with sensors) to "visualise" the cutting phenomena to support customer selection of appropriate tools and cutting methods. The lineup has been expanded with the sensing tool SumiForceTM, now available for rent.

Sensing Tool (cutting tool equipped with sensors) SumiForceTM

Sensing Tool (cutting tool equipped with sensors) SumiForceTM

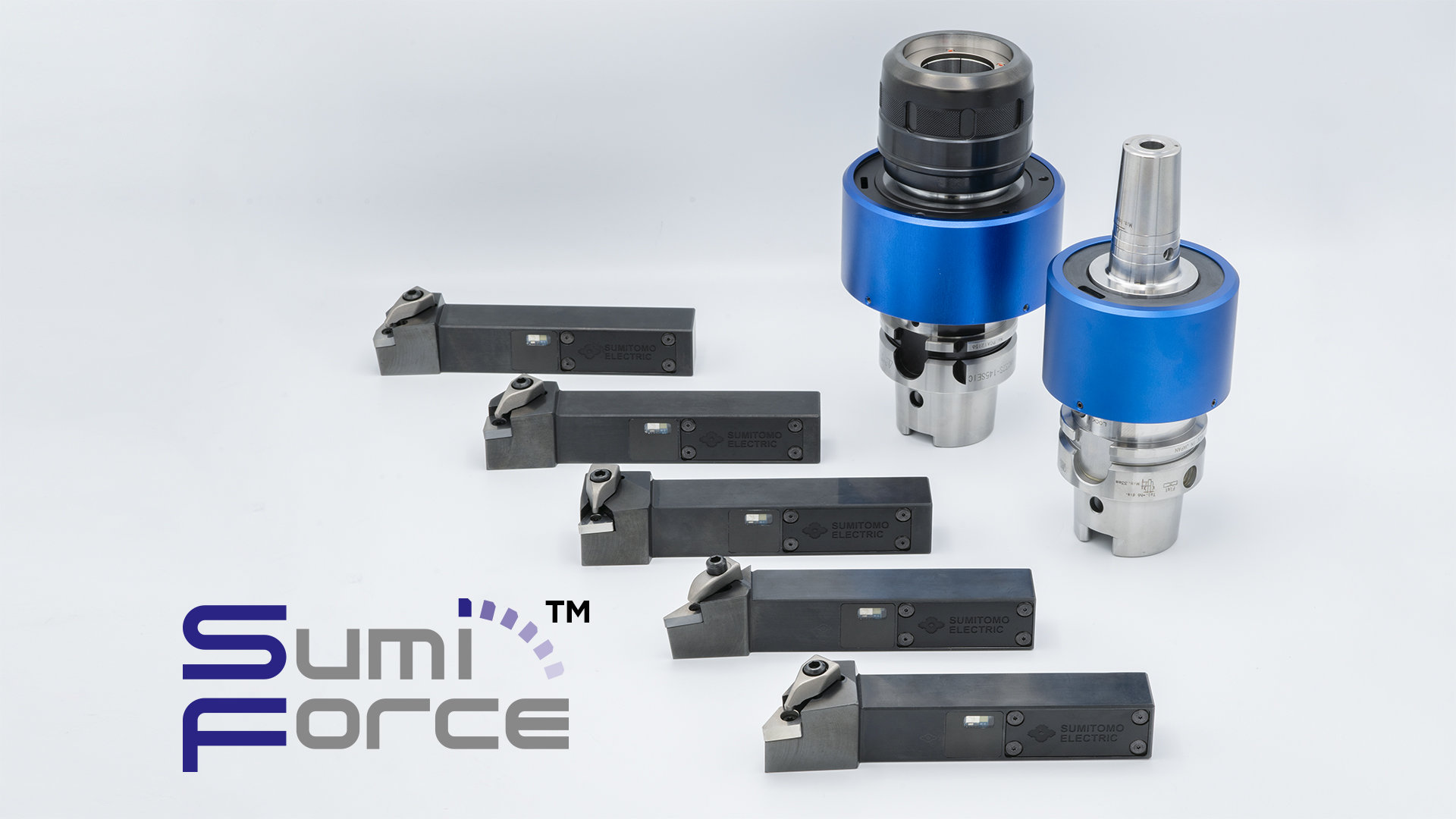

(Left) Sensing tool for turning (Right) Sensing tool for milling

In recent years, as machining becomes more complex with the emergence of complicated processes and new work materials, there is an increasing need for technology that utilises IoT to visualise the real-time machining conditions in order to quickly select appropriate machining methods and conditions.

Since November 2022, our company has offered over 50 models of sensing tools for both turning and milling at our Tool Engineering Centers through providing our support services for customer's selection of optimal machining conditions and tools. In order to make it available to more customers, the lineup has been expanded to include Sensing Tool SumiForceTM and we will start rental service of SumiForceTM sensing tools for turning (5 models) from November 2024. At JIMTOF2024, a live-stream from our Tool Engineering Center in Itami City, Hyogo Prefecture was broadcasted to demonstrate how these tools improve machining.

Don't miss the opportunity to improve your productivity and reduce machining costs with the Sensing Tool SumiForceTM.

*Cutting phenomena

Cutting force, chatter/vibration, etc.