Sustainability

To realize a sustainable society, Sumitomo Electric Hardmetal Corp. has been promoting

a variety of environmental activities including certification of ISO14001 as well as subsidiaries',

control of chemical substances, energy saving, recycling, and creation of environment-conscious products.

ENVIRONMENT Environmental Activities

SUMITOMO ELECTRIC HARDMETAL, as a member of the Sumitomo Electric Group, has defined its existence value as "pursuing top technology, evolving linking and supporting technology through innovation, and contributing to the realisation of a better society through the collective strength of the Group", and has set "a society where people can live in peace", "a comfortable and livable society" and "a green environmental society" as its social vision and will contribute to realising them.

Energy Conservation

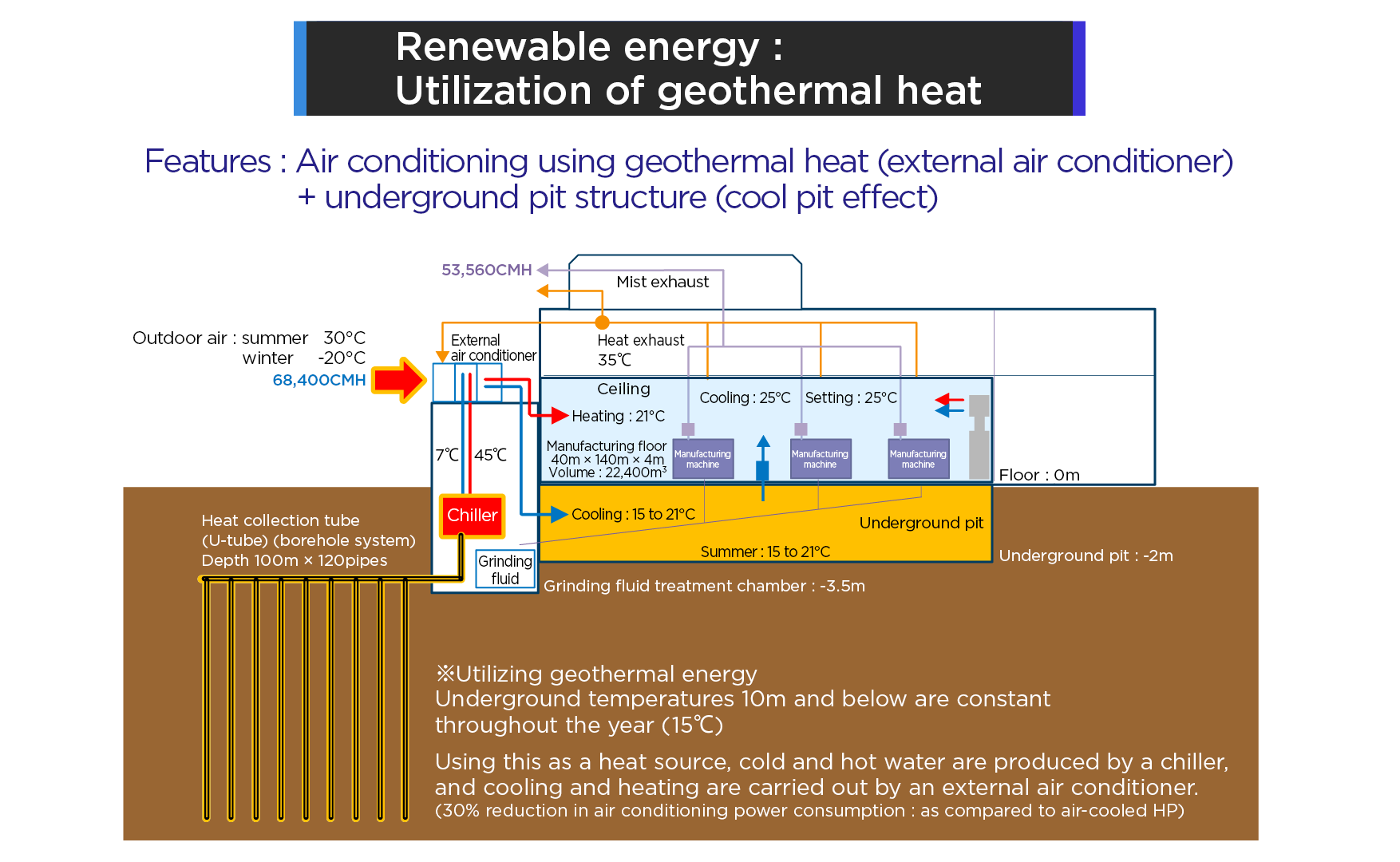

Using the temperature difference between surface and underground

Hokkaido Sumiden Precision is striving to reduce CO2 by conserving energy through the use of air conditioning equipment that use renewable geothermal heat.

While Hokkaido’s cool and dry natural environment is optimal for powder metallurgy technology, there are also large temperature differences, with outdoor air temperatures of 30 degrees in summer and -20 degrees in winter.

However, the underground temperature remains constant at 15 degrees throughout the year.

Hokkaido Sumiden Precision uses this constant geothermal heat as a heat source.

Efforts to take in outside air temperature and use a chiller that utilizes geothermal heat to produce cold and hot water for cooling and heating the factory, we have succeeded in saving energy by reducing the amount of electricity for air conditioning by 30%, as compared to conventional methods.

Energy Creation

Power generation using solar panels

In Axis Materials, solar panels with a total panel capacity of 1,000kW have been installed in its factory.

In fiscal year 2023, approximately 68.7MWh/month of electricity will be “created” through solar power generation. This contributes to a CO2 reduction of approximately 30t-CO2/ month.

In addition, we are promoting "purchased energy" in which 30% of all purchased electricity, other than solar power, is switched to electricity with a zero CO2 emission coefficient. Furthermore, the tungsten powder raw materials handled at these plants are refined using hydroelectric power as the main power source.

By using electricity derived from renewable energy sources and raw materials, we are working to save, create, and purchase energy throughout the entire factory, as well as to reduce CO2 emissions.

Complete Abolition of Harmful Substances

Sumitomo Electric Hardmetal Corp. has completely abolished materials or processes of all products designated as hazardous heavy metals including lead, mercury, hexavalent chromium, and cadmium, whose use is restricted by Europe's RoHS/ELV directives.

In addition, such hazardous organic compounds as PBB, PBDE, PFOS, PFOA, trichloroethylene, and dichloromethane are not used in all processes.

- Mercury abolished (March, 2003)

- Hexavalent chromium abolished (December, 2004)

- Cadmium abolished (January, 2006)

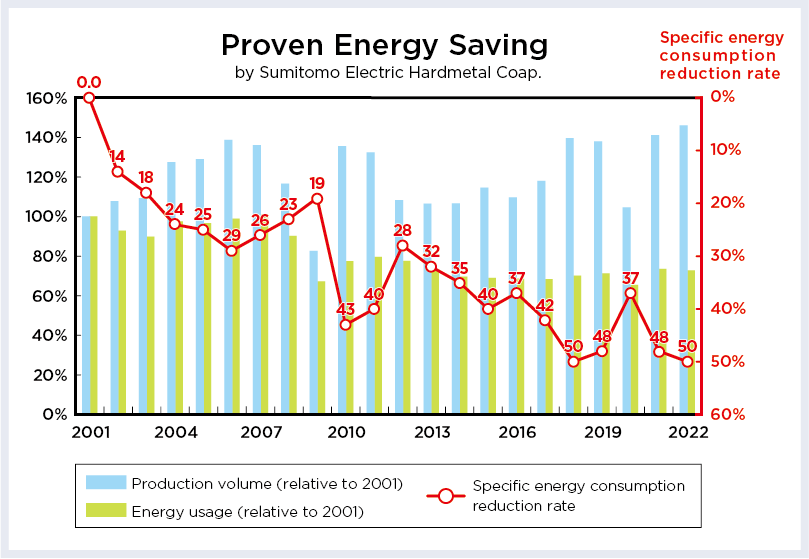

Energy Saving

To take measures against global warming, Sumitomo Electric Hardmetal Corp. has been engaged in reduction of CO2 emissions by energy saving activities, successfully resulting in a significant reduction of an energy unit.

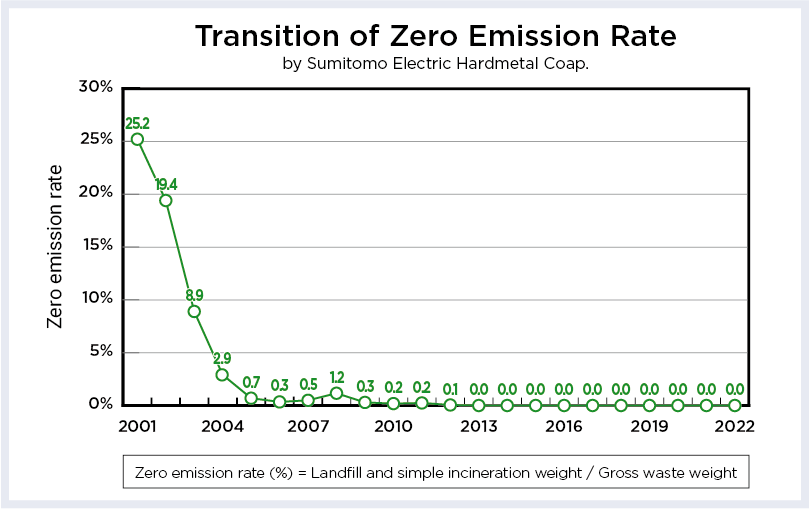

Zero Emission

Sumitomo Electric Hardmetal Corp. started zero emission activities since 2001. In 2005, we reached an annual zero emission lower than the target value of 1%, and we are still on the way of seeking for a sustained and improved rate while striving for further renovation of the activity.

ISO14001 Certification Status (including Subsidiaries)

Sumitomo Electric Hardmetal Corp. ,

certified on September 29, 2000, [No. JQA-EMI1030]

- Kyushu Sumiden Seimitsu Ltd. certified in June, 2006

- Hokkaido Sumiden Precision Co., Ltd. certified in July, 2006

- AXISMATERIA LTD. certified in May, 2007

- Tokai Sumiden Precision Co., Ltd. certified in June, 2008