NEW PRODUCTS PREVIEW

■ New Products for High-Precision Machining

Coated Carbide Grade for Small Product Turning

AC1135U

Versatile Coated Carbide Grade Specialized for Small Lathe/Autolathe Machining

Machining of stainless steel, as well as a variety of other work materials

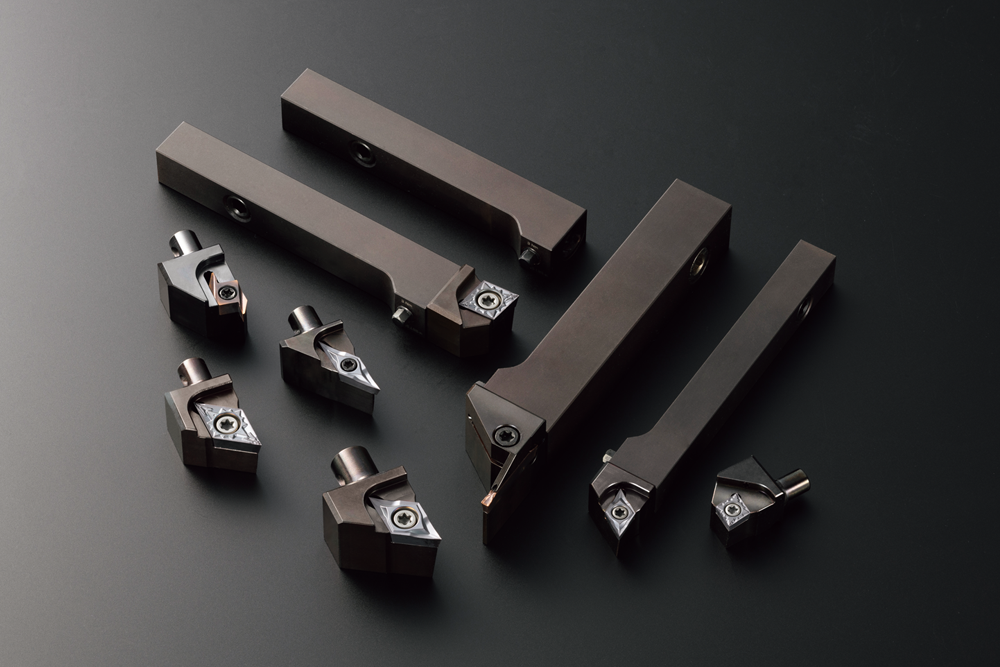

Small Lathe Tools / Indexable Head Type Quick Change Tool Holder

APM series

Sharply reduces changeover time with outstanding change repeatability

High-accuracy polygon taper shape achieveschange repeatability within 5μm

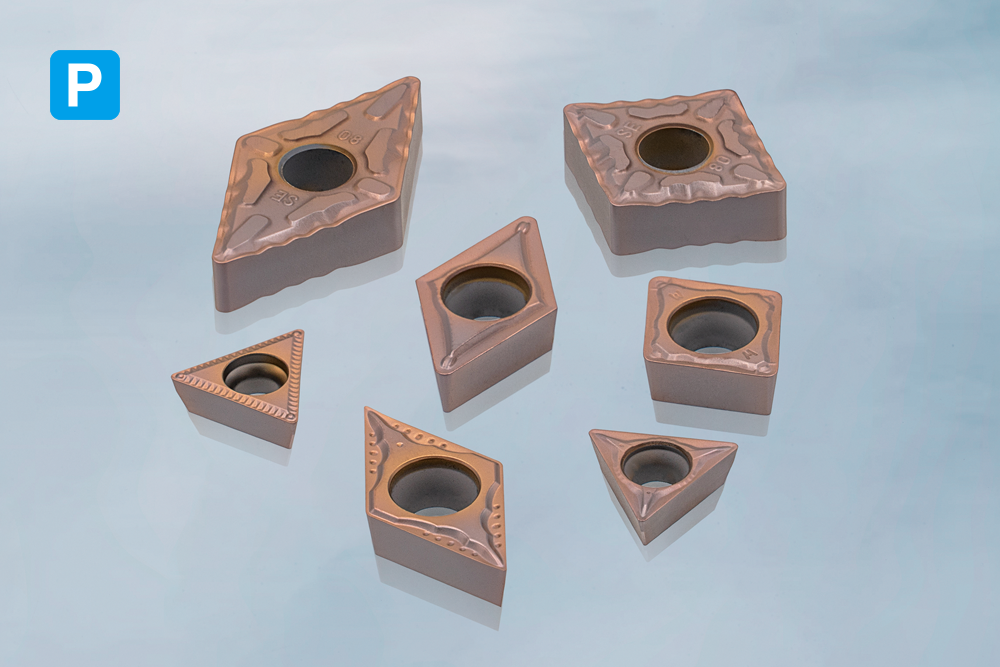

Coated Cermet Grade for Steel Turning

T2100Z

Outstanding fracture resistance

Introducing a New Coated Cermet Grade for Finishing with Outstanding Stability

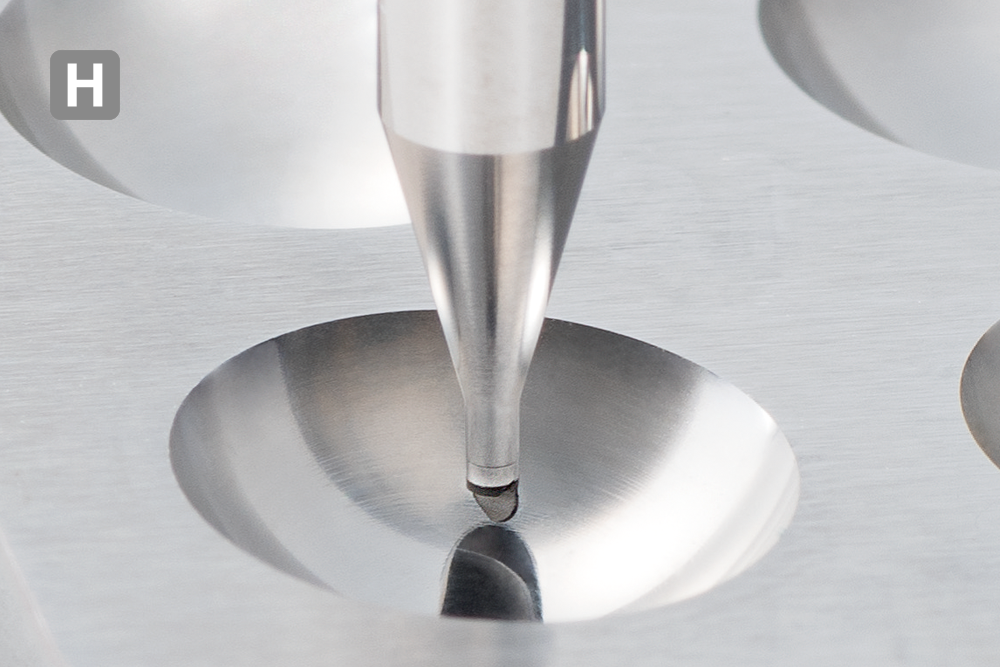

SUMIBORON Binderless Endmills for Hardened Steel

SUMIBORON Binderless Ball Endmills

Ultra-high precision for direct milling of hardened steel dies

Ideal for direct carving and finishing of hardened steel molds, contributing to reduction of polishing time

■ New Products for High-Efficiency Machining

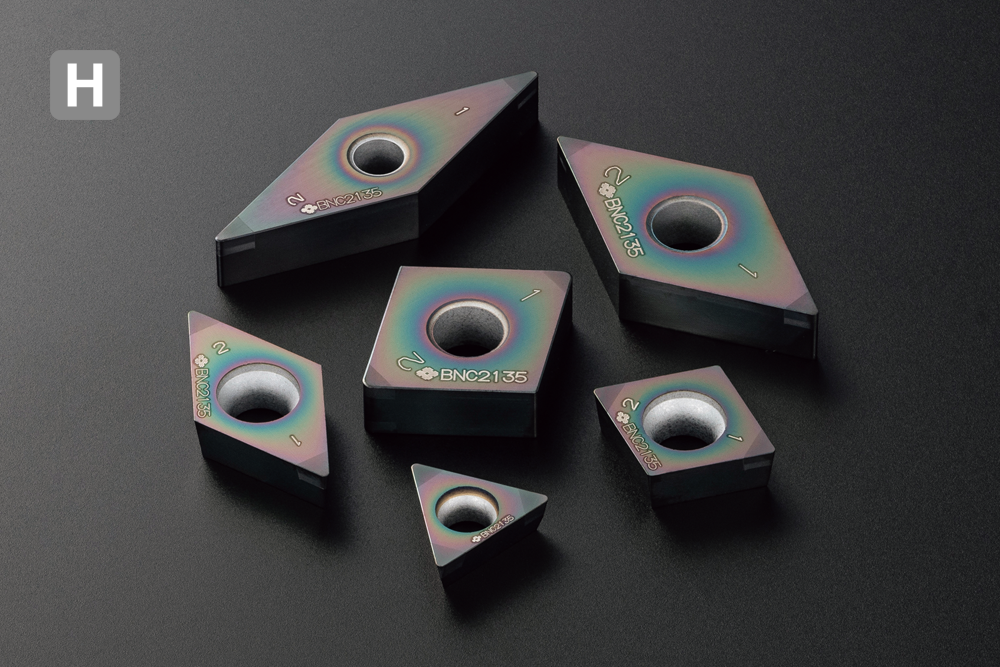

Coated SUMIBORON for Hardened Steel

BNC2135

Achieves long and stable tool life in heavy interrupted cutting of hardened steel

Utilising a highly fracture-resistant coating and a high-strength substrate to achieve long and stable tool life in interrupted machining.

Self-Restrained Tool Holders for Cut-off Machining

SEC-Cut-off Tool Holders GLC series

Optimised blade shape ideal for large-diameter cut-off machining

Achieves high machining accuracy and durability with optimised blade shape. Lineup includes steel holders, steel holders with internal coolant supply (max. cut-off dia. ø100mm), and carbide holders (max. cut-off dia. ø140mm)

Radius Milling Cutter series

SEC-Wave Radius Mill RSC series

Radius cutters for high-efficiency machining of stainless steel and exotic alloy

Small-diameter high-efficiency radius cutter. The use of 2 coolant holes realises high-efficiency milling while suppressing temperature rise in high-speed milling

Indexable Insert type Drill

SumiDrill GDX series

Realises deep hole drilling up to L/D=7

Drastically reduces drilling vibration through a high-rigidity holder design. In addition, insert design is individually optimised for the central and peripheral cutting edges to achieve excellent drilling balance and chip evacuation.

Diamond Coated Endmills for CFRP/ For Milling of Thin Plates

AVIX-F series for Milling of Thin Plates

The ultimate in CFRP machining

Realizes high-efficiency, high-quality CFRP machining through a complex cross-nicked edge shape and radical diamond coating.