Coated SUMIBORON series for Hardened Steel

The Pinnacle of High Accuracy / High-efficiency Cutting

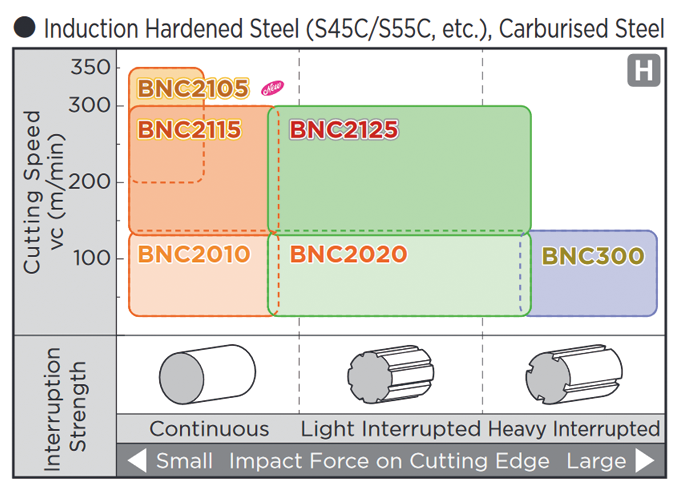

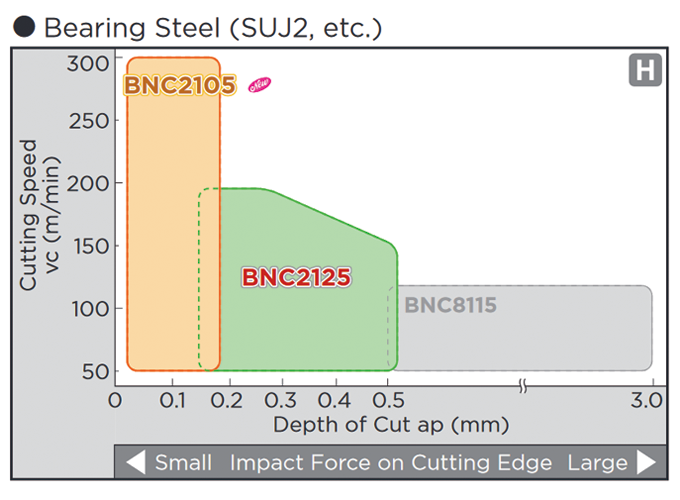

Work Material

- H

Feature

The Pinnacle of High Accuracy / High-efficiency Cutting

BNC2105

Highly wear-resistant grade for high-speed machining

Excellent wear resistant coating and CBN substrate, achieve stable and long tool life in high-speed machining.

BNC2115

The ultimate in high-precision machining of hardened steel

Utilizing a thick coating with exceptional notch wear resistance and a tough CBN substrate to achieve stable and excellent surface finish.

BNC2125

First recommendation for hardened steel machining

Combination of a tough CBN substrate and a thick coating that has a balance of wear resistance and toughness, to achieve stable machining in a wide range of applications.

BNC2010

High-precision grade for low- to medium-speed machining

Excellent wear resistant CBN substrate and coating layer, for high-precision machining that requires surface roughness and surface finish accuracy.

BNC2020

General-purpose grade for low- to medium-speed machining

Utilizing an especially high wear resistant coating and a tough CBN substrate. Excellent machining stability in low-rigidity situations and high-load cutting

BNC300

Achieves long, stable tool life even in machining with heavy interrupted cutting

Achieves long, stable tool life even on work pieces with both continuous and interrupted cutting

Application Range

Product Inquiry

Feel free to contact us for cutting and machining information

on cutting troubles and review of tooling as well as questions,

feedbacks, and requests for our home page.

Recommend

-

Solid CBN

Solid CBN- K

- H

Coated SUMIBORON BNC8115/SUMIBORON BNS8125More Detail -

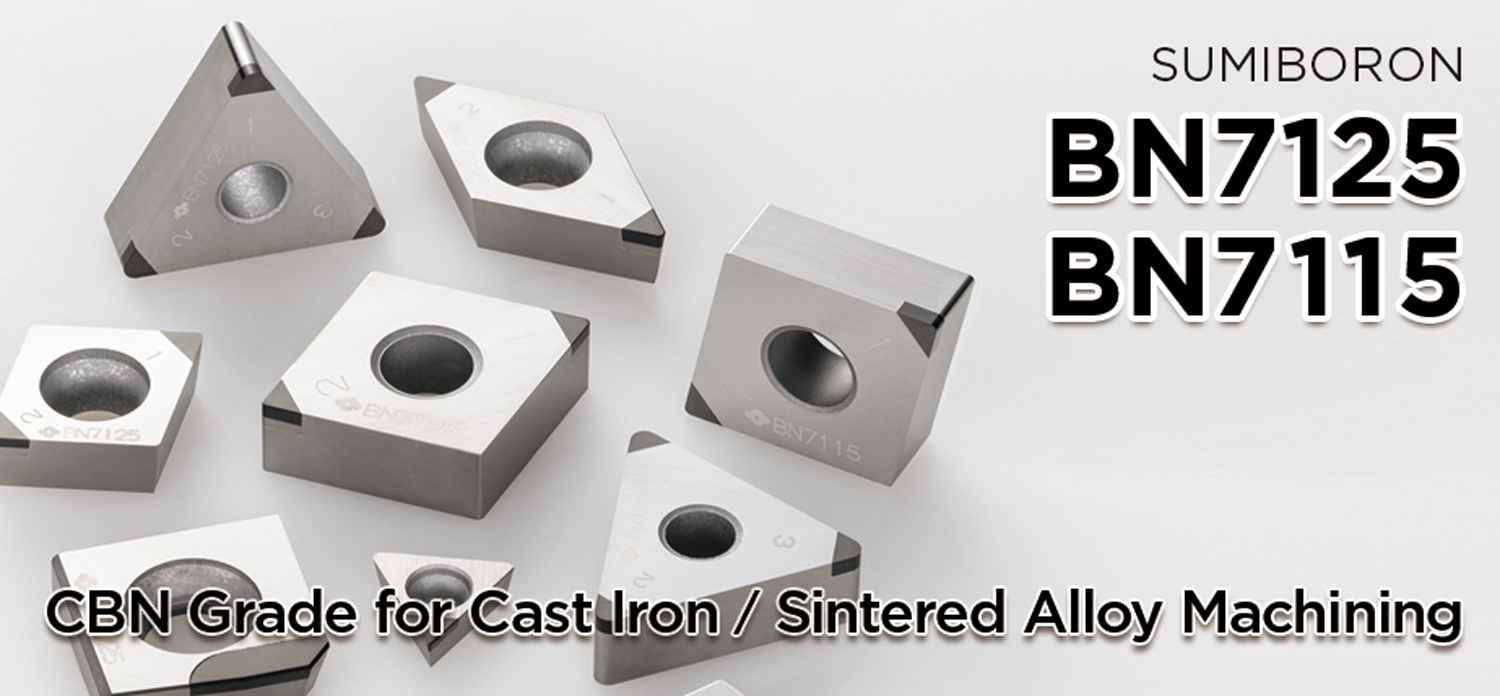

CBN Grades for Cast Iron / Sintered Alloy Machining

CBN Grades for Cast Iron / Sintered Alloy Machining- K

- PM

SUMIBORON BN7125 / BN7115More Detail -

CBN grades for hard turning

CBN grades for hard turning- H

SUMIBORON BN1000 / BN2000More Detail