SUMIBORON BN7125 / BN7115

Excellent stability in high-speed machining of cast iron and sintered alloy

Work Material

- K

- PM

Feature

Excellent stability in high-speed machining of cast iron and sintered alloy

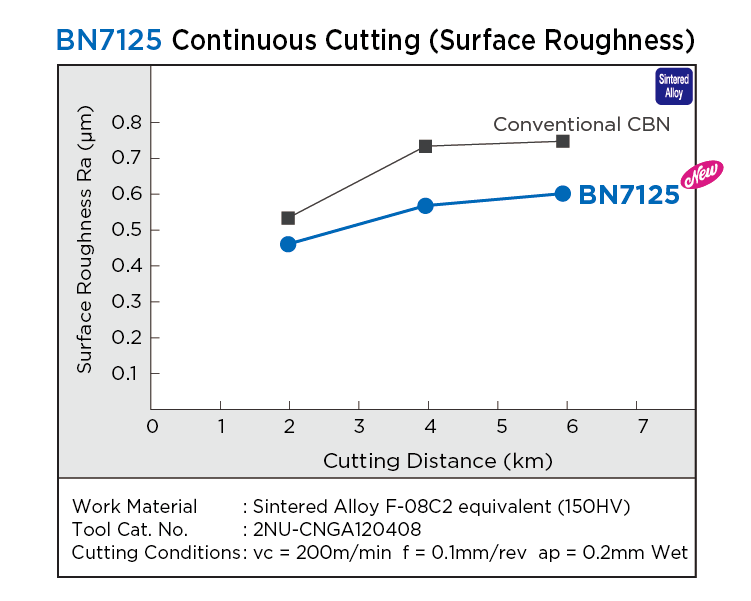

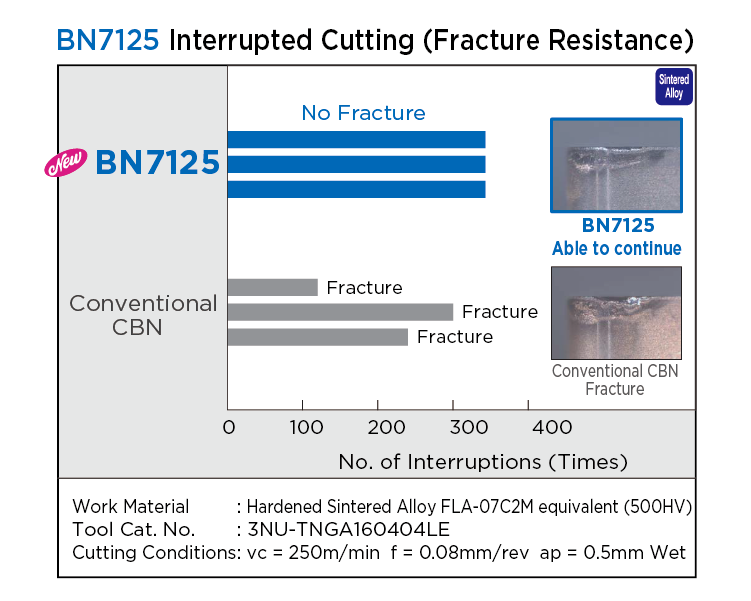

BN7125

General-purpose Grade for Cast Iron/Sintered Alloy Machining

Achieves high-effciency machining of sintered alloy with a standard + 3 types of cutting edge variations

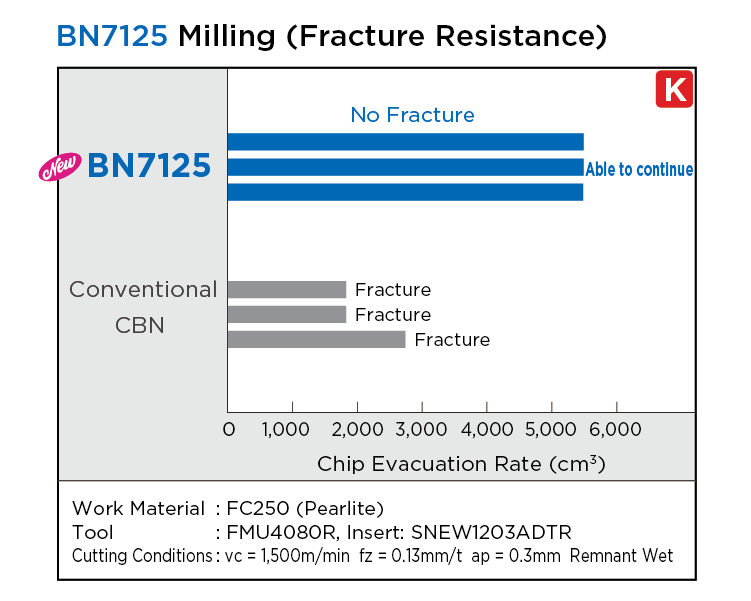

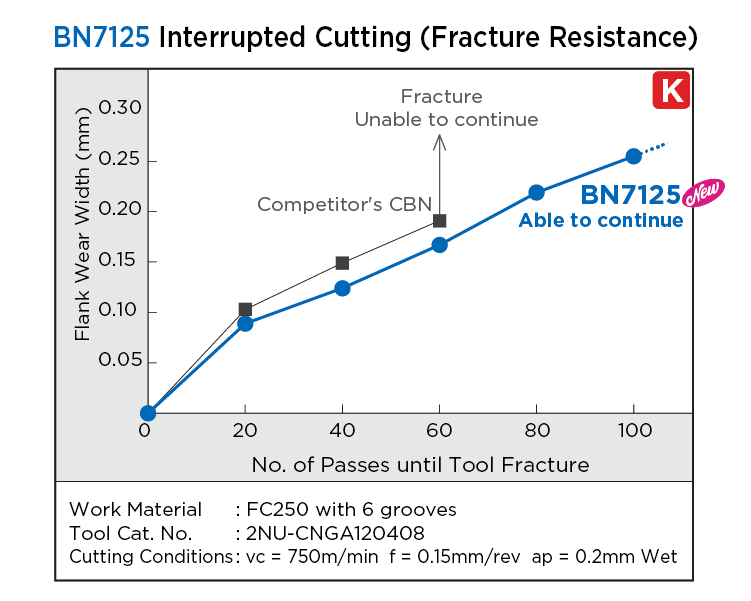

Excellent thermal crack resistance in high-speed finishing of cast iron

Also supports the machining of exotic alloys such as rolls, HSS, heat-resistant alloys, etc.

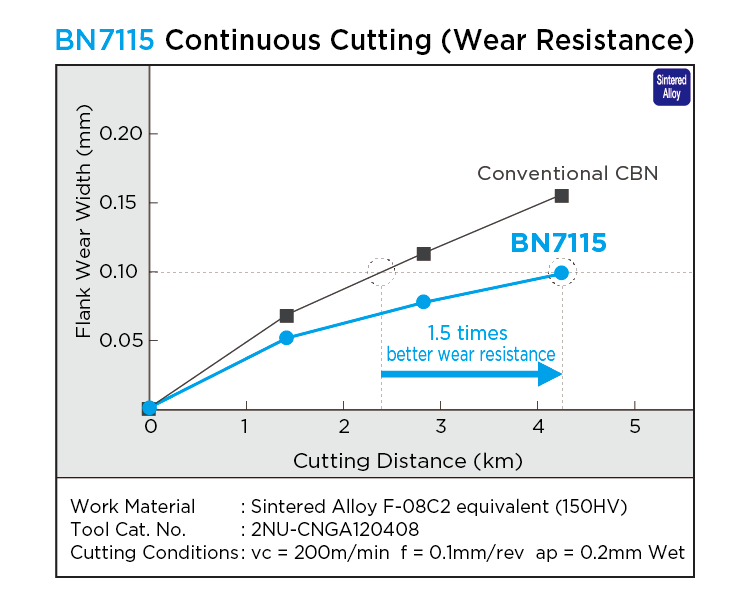

BN7115

Grade for Finishing of Sintered Alloy

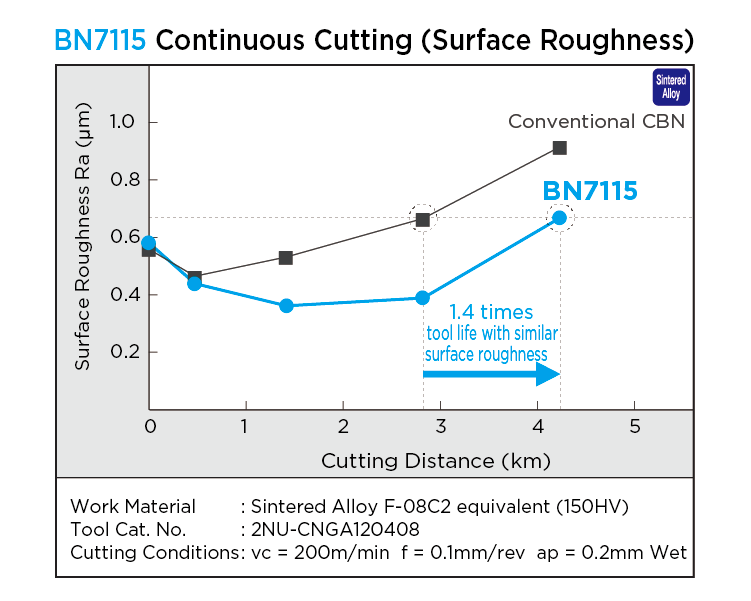

Exhibits both excellent cutting edge sharpness and fracture resistance

Stable edge sharpness suppresses burrs and tearing

Cutting Performance (Cast Iron)

Cutting Performance (Sintered Alloy)

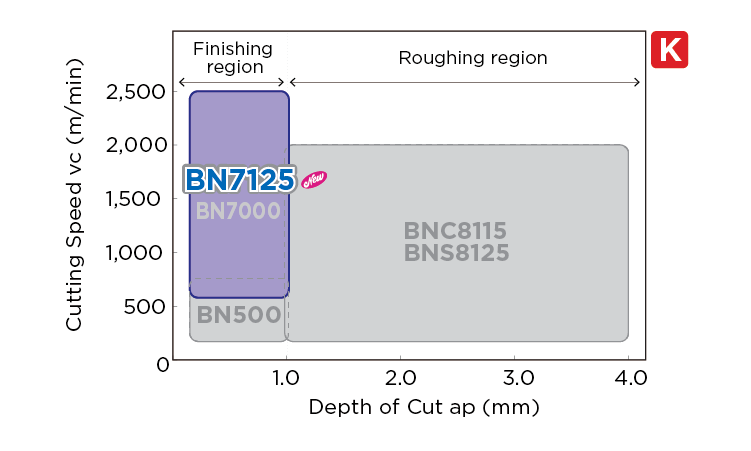

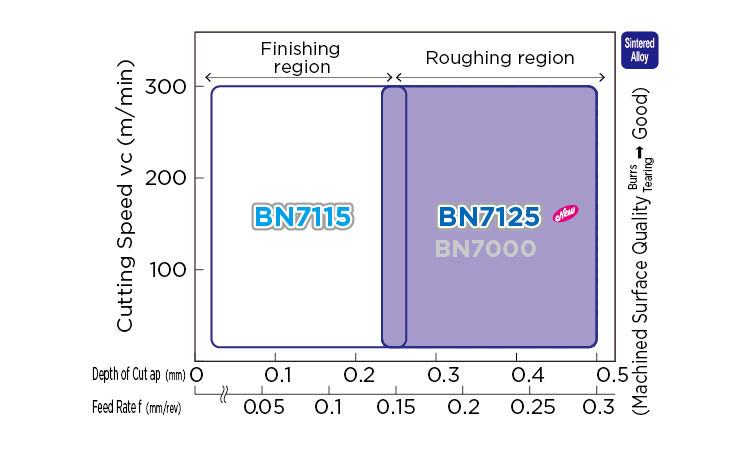

Application Range for BN7125 / BN7115

Cast Iron

Sintered Alloy

Product Inquiry

Feel free to contact us for cutting and machining information

on cutting troubles and review of tooling as well as questions,

feedbacks, and requests for our home page.

Recommend

-

Solid CBN

Solid CBN- K

- H

Coated SUMIBORON BNC8115 / SUMIBORON BNS8125More Detail -

Coated SUMIBORON

Coated SUMIBORON- H

Coated SUMIBORON series for Hardened SteelMore Detail -

SUMIBORON BINDERLESS

SUMIBORON BINDERLESS- K

- S

- CC

- HB

NCB100More Detail