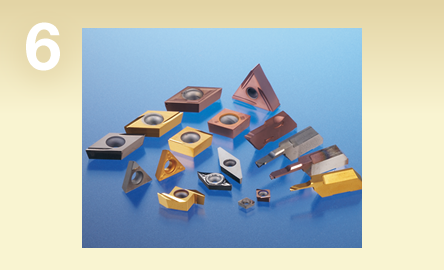

Cemented Carbide "IGETALLOY"

Cemented carbide "IGETALLOY" is an alloy which possesses both hardness, second to diamond, and toughness, similar to steel. With its 80 years of track record and an abundance of grades that meet diverse applications, the cemented carbide has gained widespread popularity with its outstanding performance.

IGETALLOY Product Lineup

A wide range of product lineups to meet all the machining needs

-

Turning tools

-

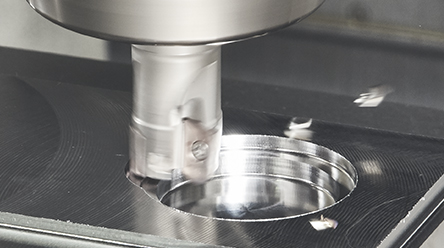

Milling tools

-

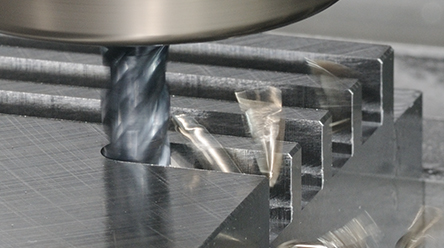

Endmills

-

Drills

To Manufacture IGETALLOY Products

-

Raw Material Powder

Using a selection raw material powders including tungsten carbide (WC) and cobalt (Co).

-

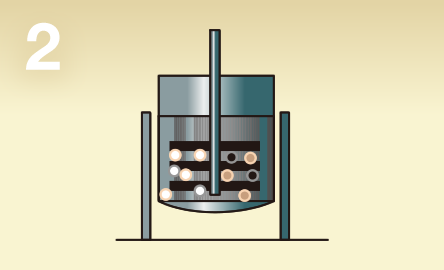

Mix

A mixer is used to mix two or more kinds of powder with liquid evenly.

-

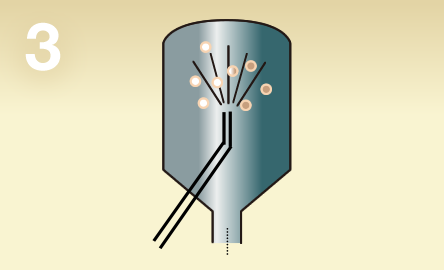

Granulation

The mixed liquid is ejected through a nozzle into a high temperature gas atmosphere for drying, thus producing the completed granular powder.

-

Press

The completed powder is filled into the mold of a pressing machine and the configured shape is formed by applying pressure.

-

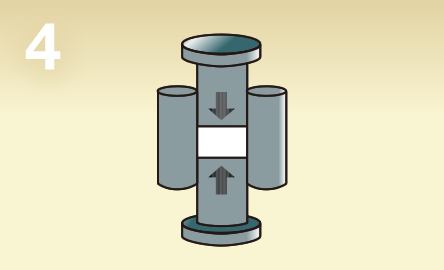

Sintering

Heating the pressed shape for a certain period of time at high temperature produces cemented carbide (sintered compact).

-

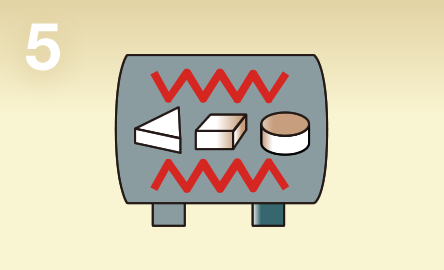

Finishing

The production is completed after going through finish grinding, with a diamond grinding wheel, and final inspection process.