Sumitomo Electric Industries, Ltd. (head office: Chuo-ku, Osaka, President: Osamu Inoue, hereafter "our company") has expanded our High-efficiency Cutter for Aluminum Alloys "ALNEX™ ANX Series," with the launch of a new wiper blade for high quality machined surface finish, from July 2022.

In recent years, the automotive industry among others, has sought to reduce the weight of parts in order to improve fuel efficiency, and the use of non-ferrous metals such as aluminum is increasing. In order to improve the machining efficiency of these parts, there is an increasing need for higher cutting efficiency, longer tool life and improved surface quality.

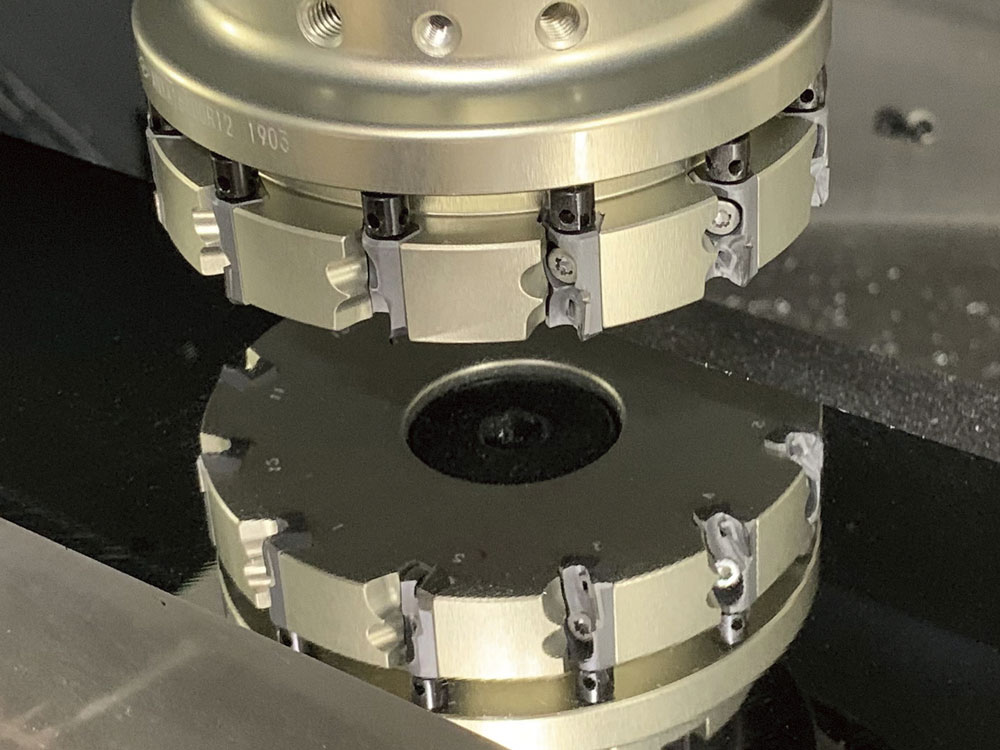

In order to respond to these needs, our company has expanded our High-efficiency Cutter for Aluminum Alloys "ALNEX™ ANX Series" (released April 2019) with the launch of the WS Type wiper blade, using a CVD (chemical vapour deposition) single-crystal diamond "SUMICRYSTAL V™ SCV10" as its cutting edge, that enables burr-free mirror finishing.

SCV10 Wiper Blade WS Type

ALNEX™ ANX Series

Mirror finish in aluminum alloy machining

1. Features

- Use of single-crystal diamond "SUMICRYSTAL V™ SCV10"

A single-crystal diamond, produced by our proprietary vapour phase synthesis technology, which has excellent wear and chipping resistance that enables long tool life and stable machining of aluminum alloys. - Realizes a burr-free mirror finish

A sharper cutting edge provides long-term suppression of burrs, which is a problem in aluminum alloy machining, as well as achieving a mirror finish.

2. Lineup

Wiper blade (grade: SCV10) 1 Series (series total: 9 cat. items)

3. Sales Plan

12 million JPY/year in the first year, 36 million JPY/year for the following year

4. Price

(Standard Product) ANB1600R-WS SCV10: 69,000 JPY (excluding tax)