Sumitomo Electric Industries, Ltd. (headquarters: Chuo-ku, Osaka, President: Osamu Inoue, hereafter "our company") has developed and launched a CBN for Powdered Metal Finishing SUMIBORON™ BN7115 in May 2021.

CBN cutting tools are used for the finishing of important powdered metal components of automobiles, household appliances, and so on. In pursuit of improved shape accuracy and machining stability in powdered metal finishing, our company has developed the SUMIBORON™ BN7115, a new CBN grade that balances superb cutting edge sharpness and fracture resistance.

1. Features

■ Realising excellent machining quality

Utilizing a unique manufacturing process that improves bonding strength between CBN particles, resulting in both excellent sharpness and chipping resistance. Superb edge sharpness in powdered metal finishing suppresses burrs and tearing, realising high-precision machining and long tool life. Long tool life can also be achieved in cast iron finishing with high-speed milling.

■ Supports diverse machining with 6 types of edge treatment

In addition to the 5 types based on existing grades, such as the LF Type (a highly versatile standard edge treatment that focuses on cutting edge sharpness for powdered metal machining) and the HS Type (with reinforced cutting edge), the US Type, with a focus on breakage resistance ideal for heavy interrupted cutting, has been added to the lineup. These 6 types of edge treatments can be used for a variety of shapes and materials of powdered metal parts.

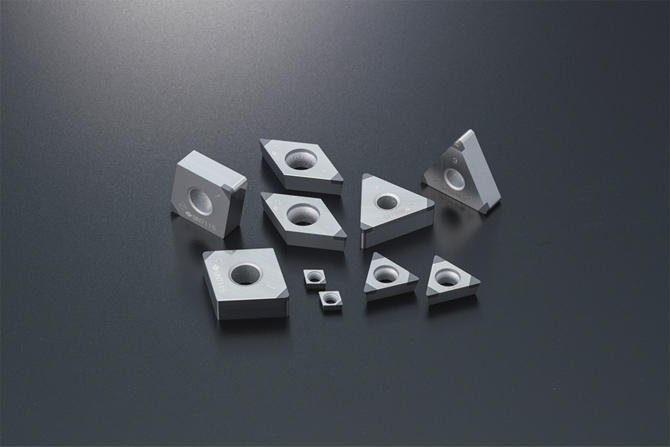

2. Lineup

ISO Turning/Milling Inserts BN7115 53 Cat. Nos.

3. Sales Plan

300 million JPY/Year in the first year, 600 million JPY/Year after 3 years

4. Price

(Standard Product) 2NU-CNGA120408 BN7115: 5,570 JPY (excluding tax)