Sumitomo Electric Industries, Ltd. (headquarters: Chuo-ku, Osaka, President: Osamu Inoue, hereafter "our company") has developed and launched new CBN grades for hardened steel machining Coated SUMIBORON™ BNC2115/BNC2125 as of July 2021.

SUMIBORON™ is a sintered material composed of CBN (cubic boron nitride), which has a hardness second only to diamond, sintered with a binder under high pressure and high temperature. As a tool material capable of machining high-hardness steel and hard-to-cut cast iron used in automotive components, its application range in cutting has expanded.

Part machining has been diversifying at manufacturing sites in recent years, leading to calls for flexible production formats suited to variable production. Further, the need for higher-functioning parts has led to increased demand for machining which can enhance added value. In pursuit of higher-precision tool material for hardened steel machining, our company has developed "Coated SUMIBORON™ BNC2115/BNC2125." These products boast stable tool life even at high-speed, high-efficiency cutting condition requirements, contributing to enhanced production efficiency.

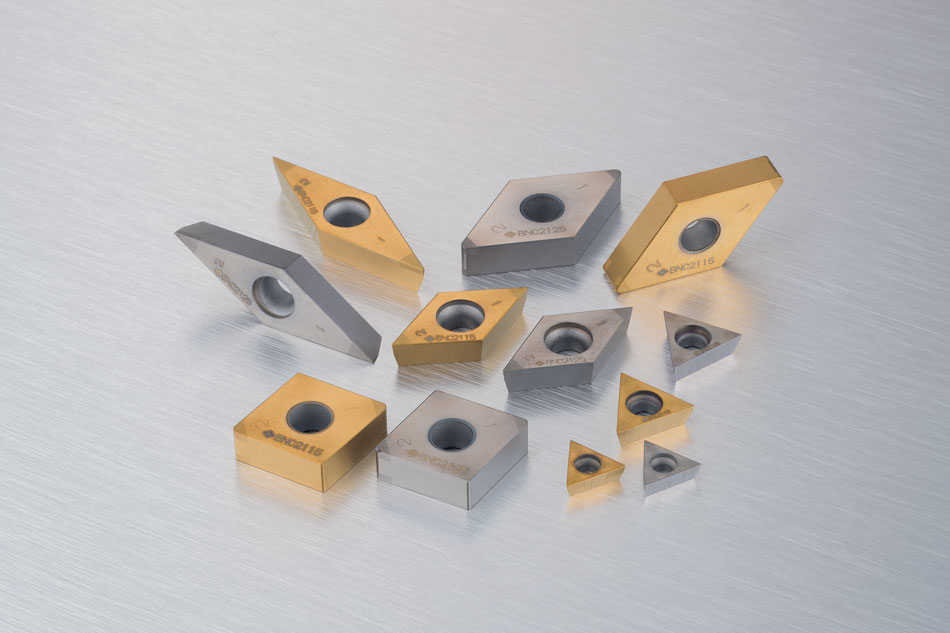

Coated SUMIBORON™ BNC2115/BNC2125

1. Features

High-precision machining grade: Coated SUMIBORON™ BNC2115

Coated SUMIBORON™ BNC2115 applies proprietary PVD multi-layered coating technology that combines a high-hardness TiAlSiN-based super multi-layered coating and a highly thermal-resistant TiCN coating, to suppress front cutting edge notch wear and improve surface finish roughness. This grade, using newly developed CBN substrate with an excellent balance of wear and chipping resistance, is suitable for high-speed, high-precision machining of hardened steel.

Grade for high-efficiency machining: Coated SUMIBORON™ BNC2125

Coated SUMIBORON™ BNC2125 uses a newly developed tough CBN substrate, with high-purity binder to suppress problematic sudden fractures in high-efficiency machining, coupled with a high-hardness, high-strength TiAlBN-based super multi-layered coating for improved wear resistance and stability in high-speed machining. Highly versatile, this is our 1st recommended grade for hardened steel machining.

2. Lineup

ISO Turning Inserts

BNC2115 168 Cat. Nos.

BNC2125 192 Cat. Nos.

3. Sales Plan

500 million JPY/Year in the first year, 3 billion JPY/Year after 3 years

4. Price

(Standard Product) 4NC-CNGA120408 BNC2115: 10,500 JPY (excluding tax)

(Standard Product) 4NC-CNGA120408 BNC2125: 10,500 JPY (excluding tax)