Sumitomo Electric Industries, Ltd. (headquarters: Chuo-ku, Osaka, President: Osamu Inoue, hereafter "our company") has developed and launched a new coated CBN grade for hardened steel turning Coated SUMIBORONTM BNC2135 for sale as of January 2025.

SUMIBORONTM is a CBN sintered material made by sintering CBN (cubic boron nitride), which has a hardness second only to diamond, with a binder under high pressure and high temperature. CBN tools are now used in an increasing range of applications such as high-precision, high-efficiency machining of the high-hardness steel and hard-to-machine cast iron used in automotive parts.

In particular, for interrupted machining*1 of high-hardness steel, the switch from grinding to cutting improves machining efficiency and contributes significantly to the reduction of machining costs. To further extend tool life, our company has developed the coated CBN grade for hardened steel machining Coated SUMIBORONTM BNC2135. This product improves production efficiency by providing stable tool life in the interrupted machining of hardened steel and other high-hardness steels.

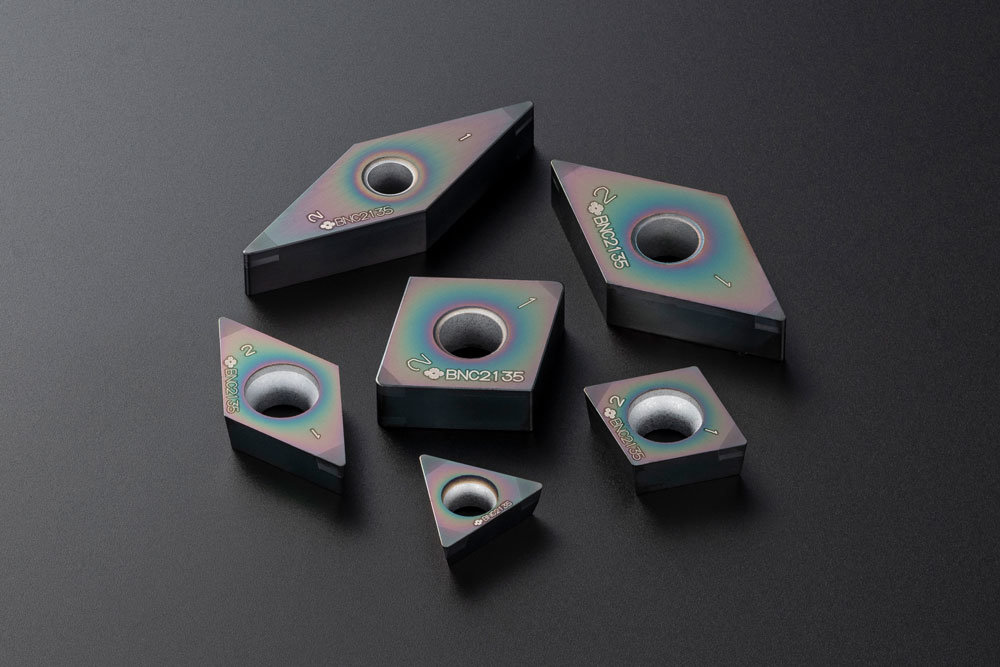

Coated CBN Grade for Hardened Steel Machining Coated SUMIBORONTM BNC2135

Coated CBN Grade for Hardened Steel Machining Coated SUMIBORONTM BNC2135

1. Features

Coated SUMIBORONTM BNC2135 has significantly improved fracture resistance through the combination of a new fine-structured and smooth surface coating, achieved by the use of a new PVD*2 coating technology, coupled with a high-strength CBN substrate with a fine and uniform structure, achieved through a new mixing and sintering process. For this reason, this is the ideal grade for interrupted machining of hardened steel.

2. Lineup

ISO Turning Inserts BNC2135 70 Cat. Nos.

3. Standard Price

6,890 to 18,600 JPY (excluding tax)/pc

*1 Interrupted machining

A cutting process where the cutting edge of the tool repeatedly engage and disengage with the surface of the workpiece that is being cut.

*2 PVD (Physical Vapor Deposition)

A method of depositing a thin physical coating on the surface of the target material in the vapor phase