Sumitomo Electric Industries, Ltd. (Head office: Chuo-ku, Osaka, President: Osamu Inoue, hereinafter referred to as "our company") has developed and launched the general-purpose positive M-class chipbreaker "GU type breaker".

In the turning of machinery components for the automotive industry and elsewhere, versatility and long tool life for the cutting tools is in growing demand in order to achieve stability and reduced costs.

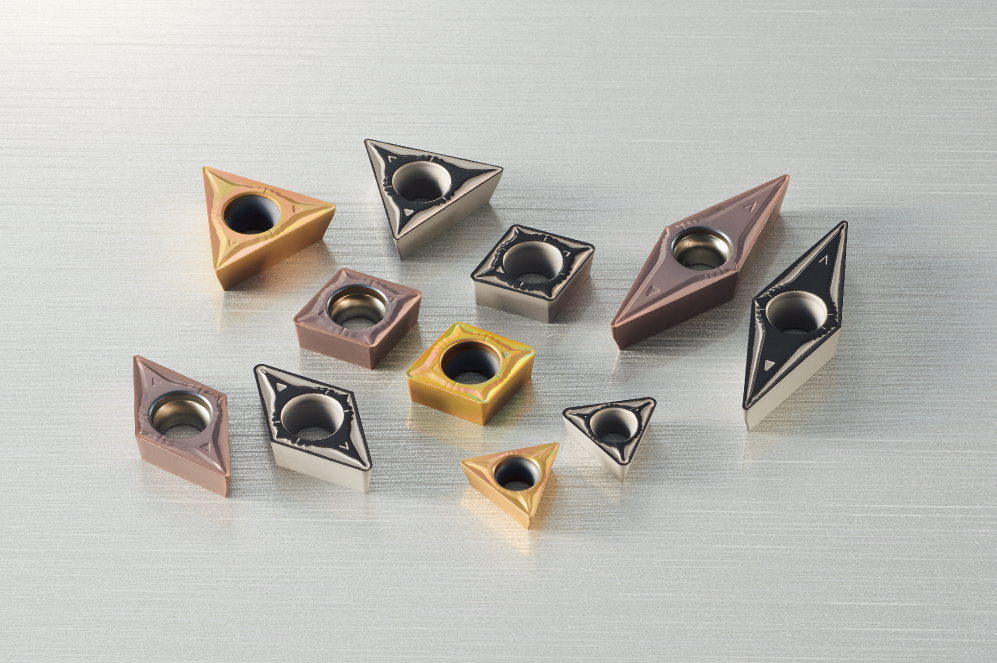

In response to this rising demand, our company has developed a general-purpose positive M-class "GU type chipbreaker" that achieves stable chip control and long tool life without sudden issues occurring during the cutting process, enabling use in a broad range of applications for light to medium turning.

1. Features

Excellent Chip Control in Wide Range of Cutting Conditions

Chipbreaker* shape design characterized by a wide chip pocket has improved chip control over a wide range of cutting conditions. This prevents chip jamming during the cutting process and achieves stable machining. In addition to alloy steel, it is also applicable to various work materials, including carbon steel and stainless steel.

Low Cutting Resistance Suppresses Chatter

The chipbreaker* shape design controls the expelled chips and serves to reduce cutting resistance and control chatter. This serves to reduce the machining load and achieve stable machining in various applications and conditions.

Improved Fracture Resistance

The double rake shape with excellent sharpness and hardness has improved the fracture resistance. This serves to reduce the frequency of tool change and achieve reduced machining costs.

2. Lineup

ISO Turning Insert: Cat. No. 207

3. Sales Plan

120 million JPY/Year in the first year, 400 million JPY/Year after 3 years

4. Price

Priced the same as our company's conventional tools

(Standard product) DCMT11T308N-GU (AC8025P) 1,130 JPY (excluding tax)

*Chipbreaker

Grooves or barriers at the cutting tip, developed for evacuation of chips generated during machining.