In December 2019, Sumitomo Electric Carbide, Inc. (Head office: Illinois, U.S.; President: Kazuyoshi Kimura), a group company of Sumitomo Electric Industries, Ltd. ("the Company") joined Oregon Manufacturing Innovation Center Research and Development (OMIC R&D), an industry-academia-government cooperative consortium for aircraft. OMIC R&D is the third aircraft-related consortium that the Sumitomo Electric Group has joined following consortiums in the UK (2017) and Germany (2018). Through the participation in these aircraft R&D consortiums established in Europe and North America, the Company will accelerate the development of cutting tools suitable for use in the aircraft industry.

OMIC R&D is an aircraft consortium established in June 2017 under the initiative of the Boeing Company, six private enterprises in Oregon, three universities in Oregon (The Oregon Institute of Technology, Oregon State University and Portland State University), and the Oregon state government. Its objective is to promote collaboration among industries, academia and government, thereby strengthening competitiveness in metalworking and developing human resources who will play key roles in the field of next-generation manufacturing. Through joint research and information-sharing with OMIC R&D, the Company will effectively use its original powder metallurgy technology and ultra-high pressure technology to develop new next-generation cutting tools required in the aircraft industry.

In the past, the Company joined the Advanced Manufacturing Research Center (AMRC) in the UK in 2017 and the International Center for Turbomachinery Manufacturing in Aachen (ICTM) in Germany in 2018, both of which are aircraft consortiums. Viewing its admission to OMIC R&D as an opportunity, the Company will grasp the latest and highest levels of European and North American market needs for aircraft engine and air frame structural parts in order to accelerate the development of high-efficiency, long-life cutting tools satisfying these needs and introduce these new tools into the market on a full-scale basis.

Center right: Mr. Craig Campbell, OMIC

Center left: Kazuyoshi Kimura, president of Sumitomo Electric Carbide, Inc.

In addition to its admission to OMIC R&D, the Company will put a variety of other strategies into motion to make full-scale expansion of its cutting tool business in the aircraft industry, such as technical support by its European Design and Engineering Center and America Tool Engineering Center, quick response to the demands for non-standard special-purpose products by its local production bases, and converting seeds of an idea into products in Japan.

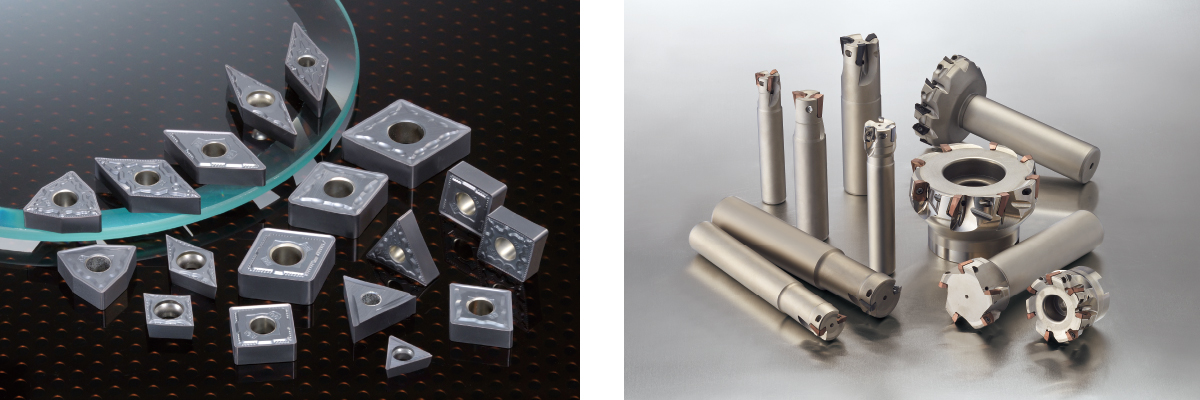

Products the Company intends to expand sales in the aircraft industry

Left: Coated Grades for Exotic Alloys, AC5015S/AC5025S

Right: High-Precision shoulder Milling Cutter for General-Purpose, SEC-WaveMill WEZ™ series

Materials for airframes are said to be hard to machine. To further increase the share of its products in the booming aircraft manufacturing market, the Company will efficiently use its unique powder metallurgy and ultra-high pressure technologies cultivated through its past cutting tool business and will also actively participate in the above aircraft consortiums and other aircraft R&D projects.

以上