Sumitomo Electric Industries, Ltd. (head office: Chuo-ku, Osaka, President: Osamu Inoue) has developed and launched Smart Damper™ for Internal Boring SDB Type. Available for sale as of August 2021, this product improves machining quality and tool life by suppressing chattering.

In internal boring of cylindrical workpieces, it is generally necessary to have a longer tool overhang, which is therefore more prone to chattering (tool vibration) as compared to external turning. Chattering leads to various problems such as decreased machining quality and shortened tool life. Particularly in recent years, chattering is more likely to occur due to the increase in machining of exotic materials, that places a greater load on the tool, and longer tool overhang to accommodate complicated work shapes. Amid heightened expectations of high-efficiency machining, how to suppress chattering has become a major issue.

So far, through the supply of the SEC-Anti-Vibration Boring Bar SumiTurn™ X-Bar, our company has achieved high vibration damping performance in internal boring with tool overhang ratio (L/D)*1 up to 6, which has been well received. However, in response to growing need for anti-vibration tools, we have developed the Smart Damper™ for Internal Boring SDB Type, which also supports large overhangs. Through the use of a special damper mechanism which absorbs vibration, the SDB Type suppresses chatter even at long overhangs of L/D=8 or so, realising improved machining quality and longer tool life.

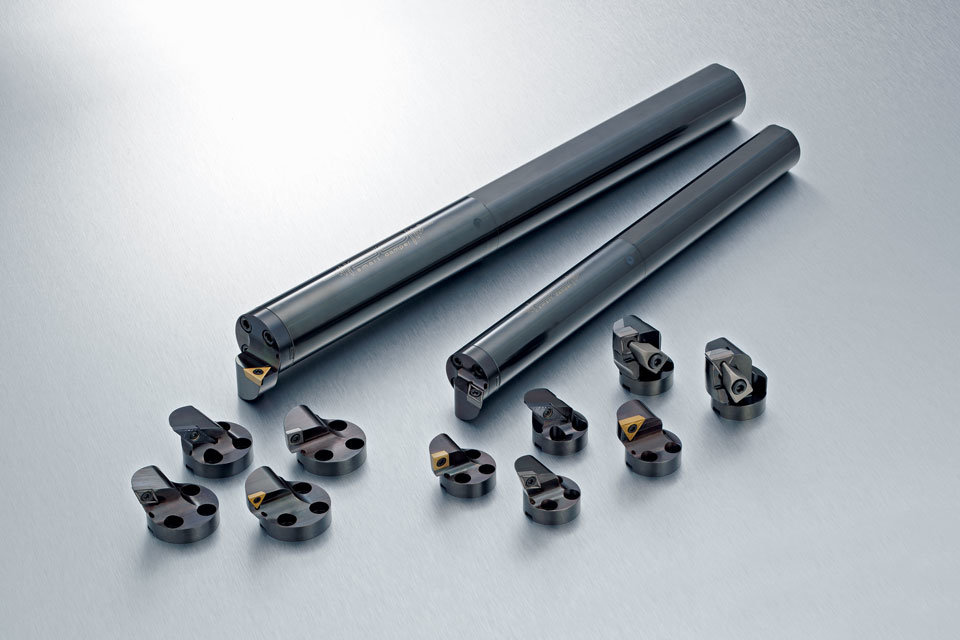

Smart Damper™ for Internal Boring SDB Type

1. Features

New anti-vibration mechanism offers superb vibration damping performance

A special damper mechanism is built in to suppress chatter for large diameter bars with long overhang of L/D=5 to 8. This realises improved machining quality and longer tool life.

Utilising indexable heads

The head portion, that holds the insert, is interchangeable and is attached to the main body that has an anti-vibration mechanism. By changing the head alone, a variety of inserts, both positive and negative types, can be use.

Utilising internal coolant supply

Coolant can be supplied near the insert position to the cutting edge. This extends tool life as well as improving the chip evacuation which can easily present issues during internal boring.

2. Lineup

・ (Body) S-SDB Type 2 Cat. Nos.

・ (Head) SDB Type 36 Cat. Nos.

3. Sales Plan

10 million JPY/year in the first year, 20 million JPY/year after 2 years

*1 Tool overhang ratio (L/D): The ratio of the tool overhang amount (L) to tool diameter (D). The larger the value, the lower the tool rigidity becomes, making chattering more likely.

* Smart Damper™ is a registered trademark of BIG DAISHOWA Co., Ltd.