Sumitomo Electric Industries, Ltd. (Head office: Chuo-ku, Osaka, President: Osamu Inoue) has developed and launched inserts for deep grooving SEC-Grooving Tool SSH Type as of October 2022.

In machining of various machine parts, especially for the automotive industry, grooving is widely used to create a recess on rotating shafts. In particular, chip evacuation is more difficult in internal grooving of small parts than with normal grooving as chips sometimes remain within the parts. In addition, there are other problems such as vibration-prone tools which degrade the machined surface.

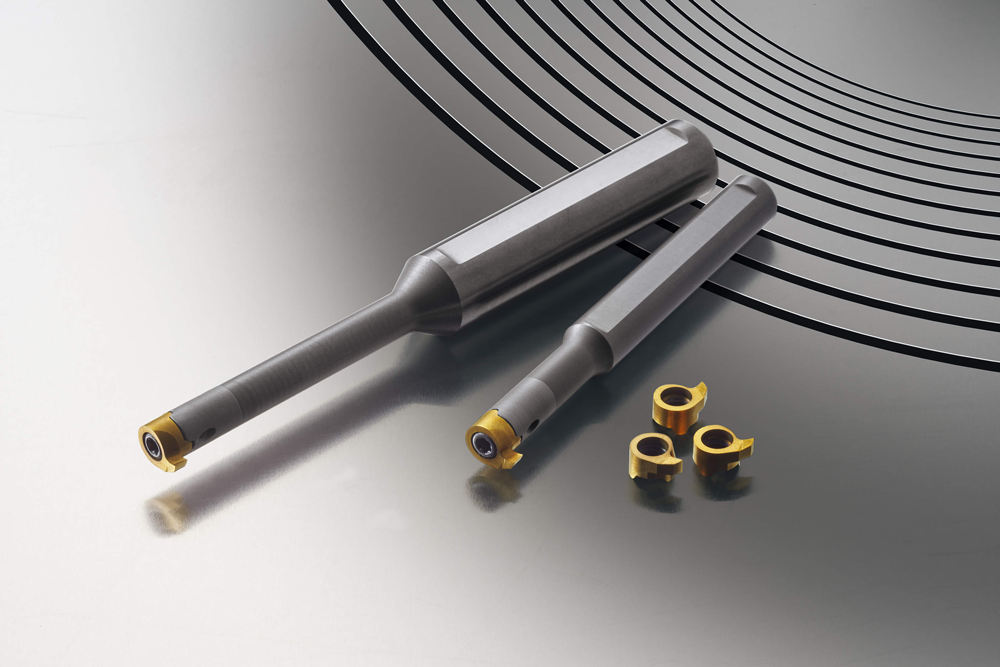

To resolve these issues, the SEC-Grooving Tool SSH Type which was launched in April 2019, offers excellent chip evacuation capabilities and high rigidity by suppressing chip issues arising during internal grooving of small parts, thus realising excellent machined surface quality.

Now in order to respond to customer needs for deep grooving, we have expanded and offered for sale size 09/10 inserts, which handle groove depths of 2mm (min. bore dia. ø9mm) and 3mm (min. bore dia. ø10mm), deeper than the existing 1mm groove depth (min. bore dia. ø8mm).

SEC-Grooving Tool SSH Type

1. Features

(1) Excellent chip evacuation capabilities

The chipbreaker* shape was designed with small-diameter internal grooving in mind, controls the shape and flow direction of the chips generated during machining to realise excellent chip evacuation. In addition, the holder with through-tool coolant supply further enhances chip evacuation effect by discharging coolant from the coolant holes.

(2) Tough carbide body suppresses vibration during machining

The SSH Type uses carbide for the holder body, sharply reducing vibration during machining and realising high-quality machined surfaces.

(3) Outstanding machining quality

The combination of a sharp cutting edge design and a smooth high-adhesion coating layer maintains excellent cutting edge sharpness for a long period of time, suppressing tearing on the machined surface from initial tool use until tool replacement, thus realising outstanding machining quality.

2. Lineup

・Min. Bore Dia. ø9mm Insert: Total of 8 Cat. Nos.

・Min. Bore Dia. ø10mm Insert: Total of 8 Cat. Nos.

3. Sales Plan

40 million JPY/year in the first year, 70 million JPY/year after 2 years

4. Price

Insert: 4,490 JPY (excluding tax)

*Chipbreaker

Grooves or barriers at the cutting tip, developed for evacuation of chips generated during machining.