Sumitomo Electric Industries, Ltd. (head office: Chuo-ku, Osaka, President: Osamu Inoue, hereafter "our company") has developed a low resistance tangential insert side cutter SEC-Sumi Dual Mill™ TGC Type for sale as of November 2022.

Side cutters can be used in a wide range of applications like machine parts for automobiles, machine tools, construction machinery and so on. In general, when machining with side cutters, a long tool overhang can lead to problems such as deterioration of machined surface quality as well as decreased tool life due to chatter and vibration. Therefore, in response to the increasing need for low-resistance products that suppress chatter and vibration, cutters with sharp cutting edges are required. Likewise in recent years, side cutters have also been called on for high-efficiency machining while suppressing power consumption for eco-friendly purposes.

In response to these requirements, our company has developed a low resistance tangential insert side cutter SEC-Sumi Dual Mill™ TGC Type. The SEC-Sumi Dual Mill™ TGC Type exhibits excellent edge sharpness due to a sharpness-focused design which include a cutting edge inclination angle of +10°. In addition, using insert grade ACU2500 with excellent chipping and wear resistance, contributes to solving issues such as improving productivity, reducing tool costs and helping users save power through high efficiency machining.

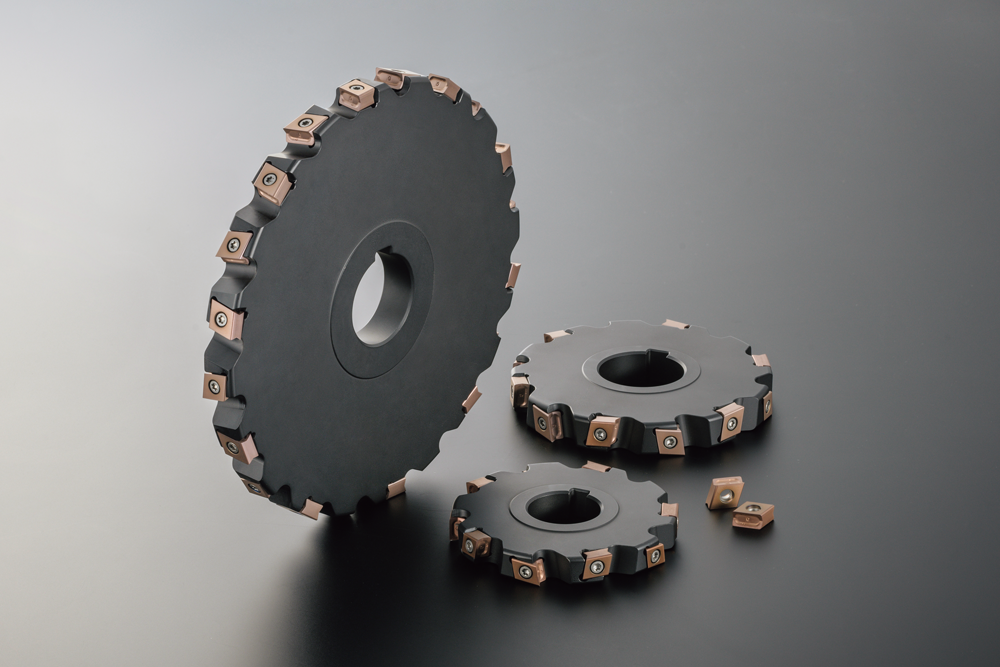

SEC-Sumi Dual Mill™ TGC Type

1. Features

(1) Side cutter suitable for a variety of applications

Made-to-order body designs are available with width of cut 17mm and up. Suitable for various applications such as groove milling and shoulder milling.

(2) Realises low resistance and low-vibration milling

Cutting edge inclination angle of +10° is designed to focus on sharpness for excellent cutting performance. Stable machining is possible by suppressing chatter and vibration, even when machining low-rigidity workpieces that are prone to unstable machining.

(3) Realises excellent surface quality

Proprietary insert array design minimizes joint steps at the groove bottom for excellent machined surface quality.

2. Lineup

Insert: Total of 5 Cat. Nos. (Grade: ACU2500)

(Body: Made-to-order)

3. Sales Plan

100 million JPY/Year in the first year, 200 million JPY/Year after 2 years

4. Price

Insert: 3,340 JPY (excluding tax)

(Body: Made-to-order)