MULTIDRILL MDC series

Ideal for Chamfering on Small Lathes / Autolathes

Work Material

- P

- M

- K

Feature

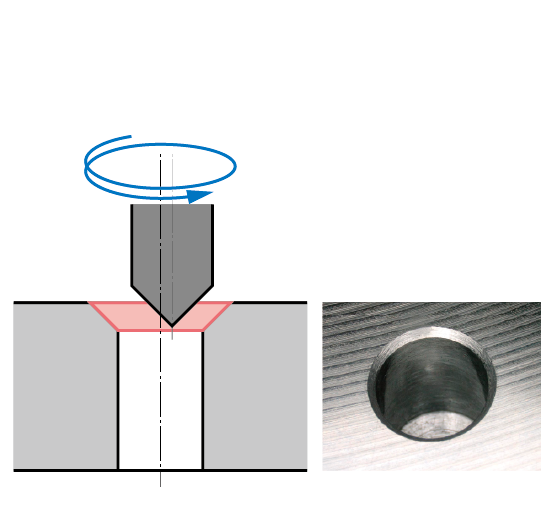

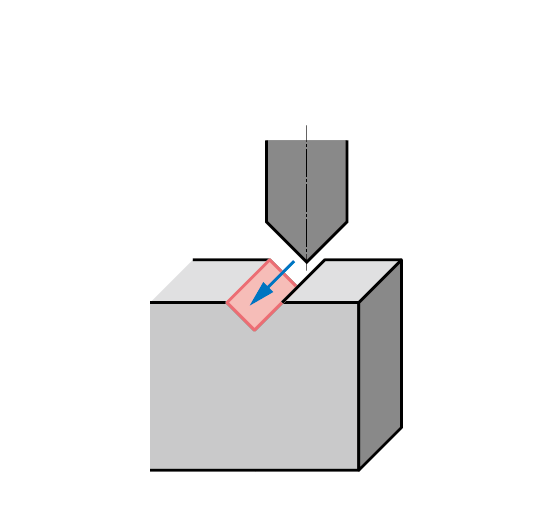

Ideal for Chamfering

on Small Lathes / Autolathes

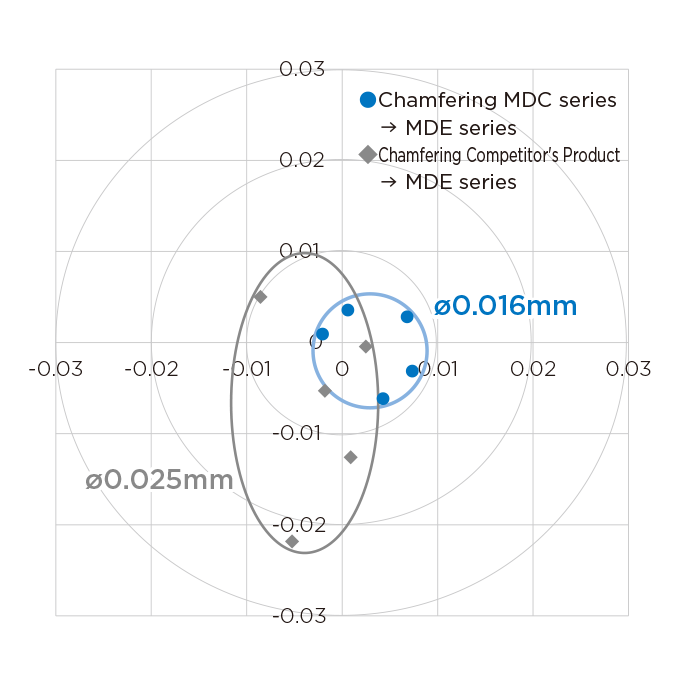

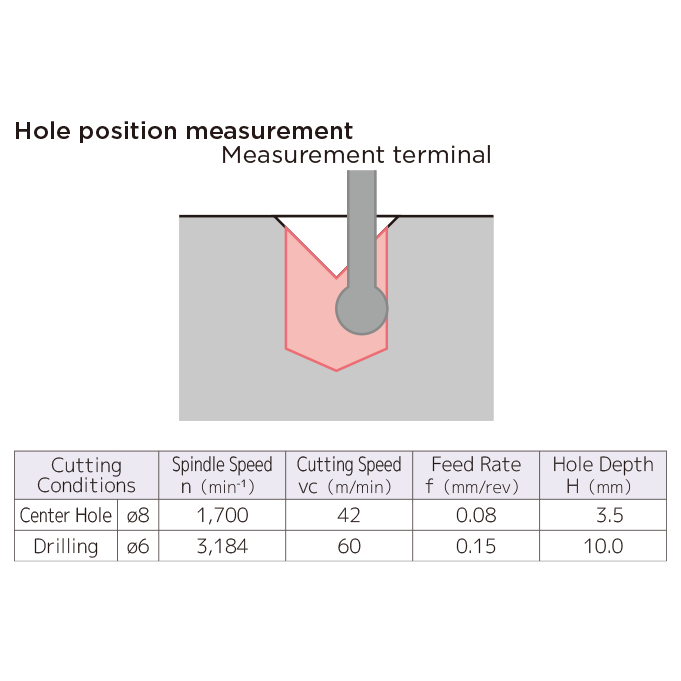

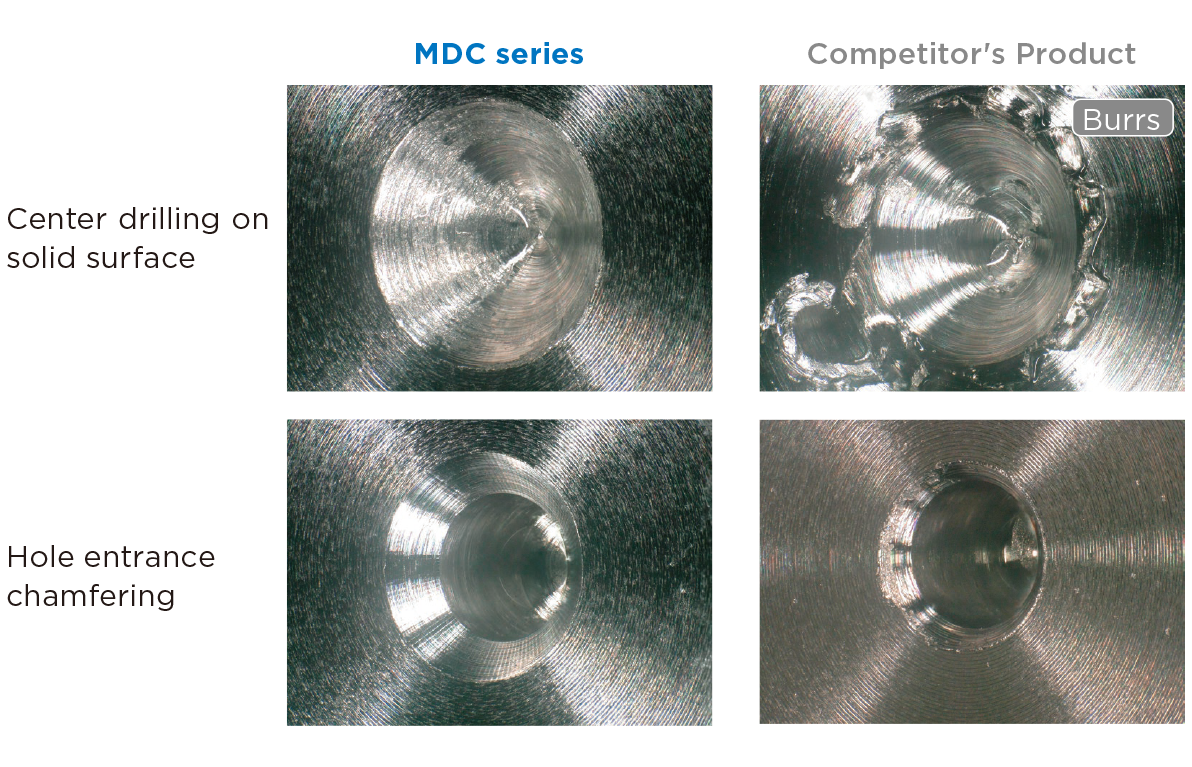

Hole Position Accuracy

Center drilling with MDC series achieves excellent drilled hole positioning

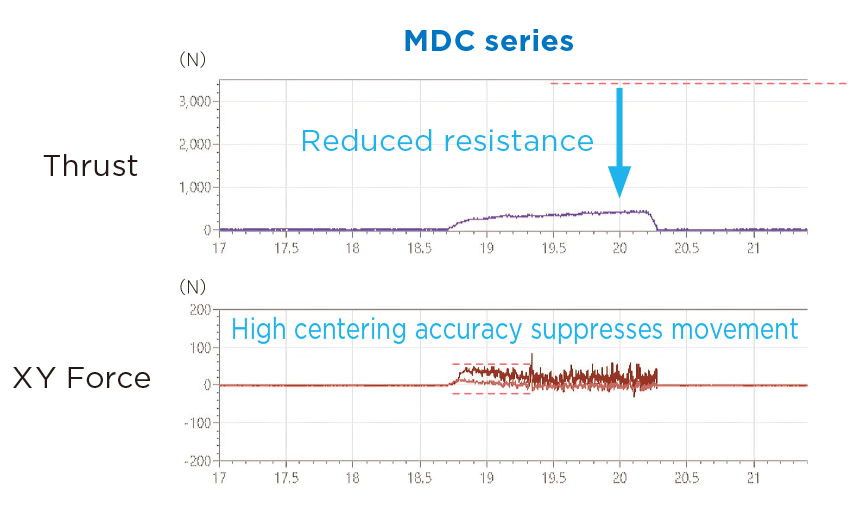

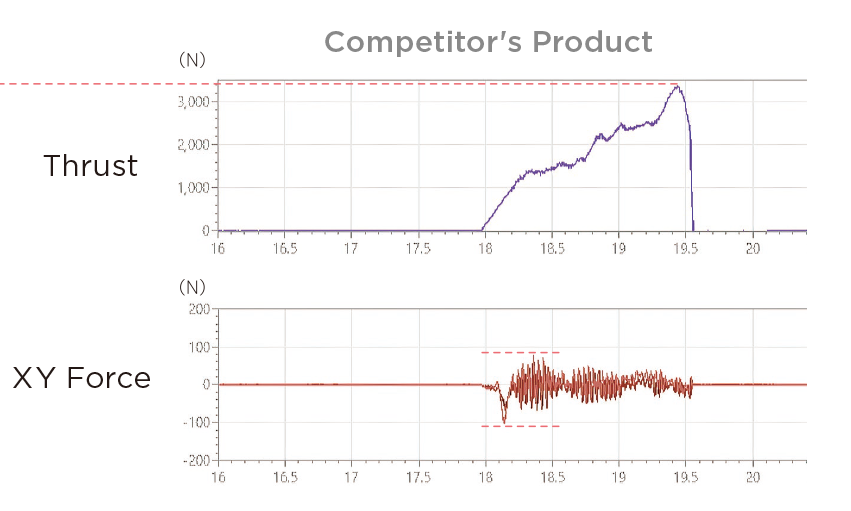

Reduced Cutting Force

Work Material: S50C Machine: Vertical Machining Center BT30 Cutting Conditions: n=1,700min-1 f=0.08mm/rev External Coolant Supply (Water-soluble)

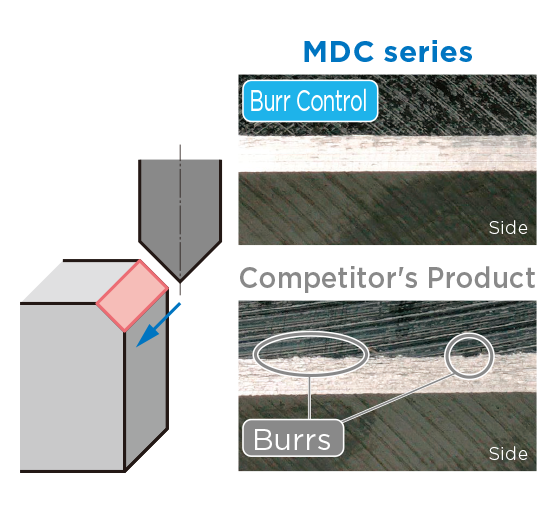

Burr Control

Work Material: SUS316L Machine: Autolathe Cutting Conditions: n=4,500min-1 f=0.04mm/rev External Coolant Supply (Oil-based)

Sharp cutting edge keeps machining burrs small

Also Supports Milling Applications

Contouring

Chamfering

Groove Milling

Sharp cutting edge keeps machining burrs small

Product Inquiry

Feel free to contact us for cutting and machining information

on cutting troubles and review of tooling as well as questions,

feedbacks, and requests for our home page.

Recommend

-

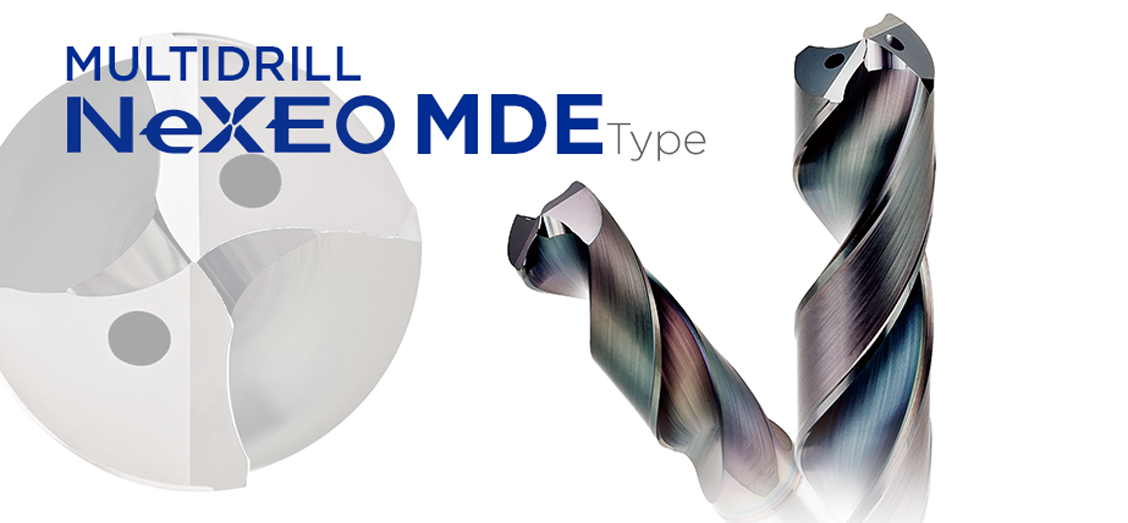

Coated carbide drills

Coated carbide drills- P

- M

- K

- S

- H

NeXEO MDE seriesMore Detail -

Coated carbide drills for stainless steel

Coated carbide drills for stainless steel- M

- S

MULTIDRILL MDM seriesMore Detail -

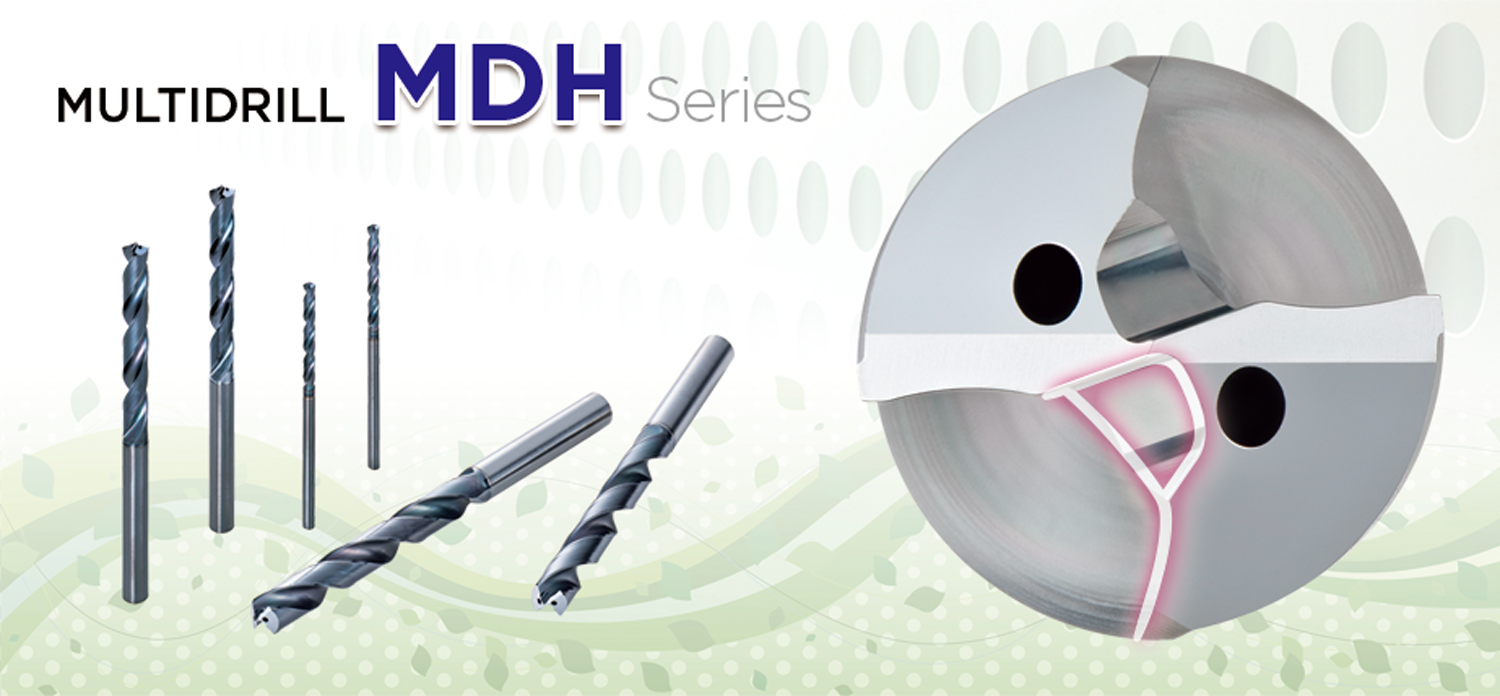

AURORA Coat Drills for Non-Ferrous Metal Drilling

AURORA Coat Drills for Non-Ferrous Metal Drilling- P

- K

MULTIDRILL MDH seriesMore Detail