Mold Finish Master SUMIBORON BNBR series / BNBP series

For hardened steels even with hardness exceeding 60HRC!!

Work Material

- H

Feature

For hardened steels even with hardness exceeding 60HRC!!

Radius Endmills BNBR series

Improved machined surface quality through use of a wiper edge (available on ø1.0mm or larger endmills).

Achieving longer tool life with the combination of SUMIBORON BNX20, which has excellent wear resistance, and an optimised cutting edge design.

Excellent wear resistance delivers almost 10 times longer tool life than carbide endmills

Ballnose Endmills BNBP series

Achieves high precision machining with precise ball radius of ±0.005mm.

Achieving stable interrupted milling with the combination of SUMIBORON BN350, which has excellent fracture resistance, and a cutting edge with a negative rake angle design.

Strong cutting edge enables use in roughing applications.

Excellent wear resistance and machined surface quality.

Small center cutting edge maintains sharpness over many hours. Stable machined surface quality!

Product Inquiry

Feel free to contact us for cutting and machining information

on cutting troubles and review of tooling as well as questions,

feedbacks, and requests for our home page.

Recommend

-

“Global Standard” Solid Endmill

“Global Standard” Solid Endmill- P

- M

- K

- S

- H

GSX Mill seriesMore Detail -

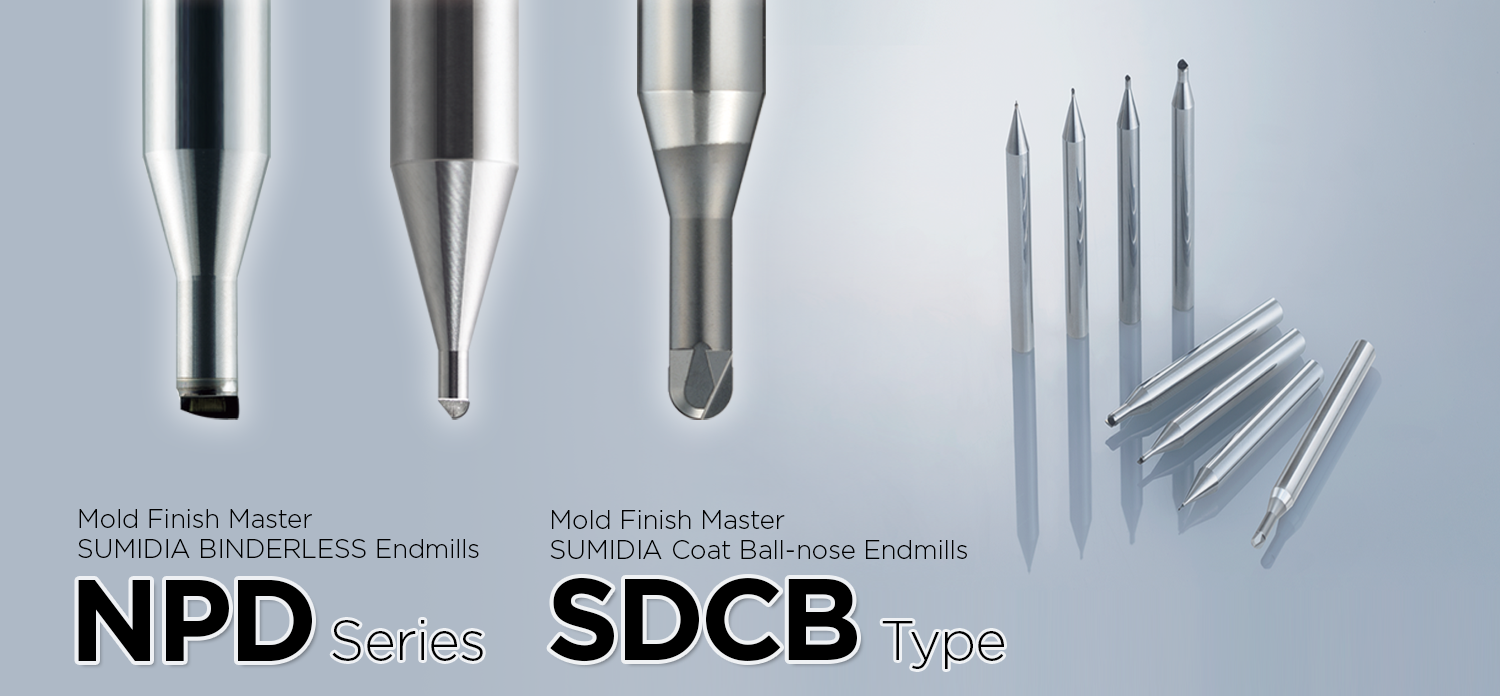

Direct milling on cemented carbide materials

Direct milling on cemented carbide materials- CC

- HB

SUMIDIA BINDERLESS Endmills NPD seriesMore Detail -

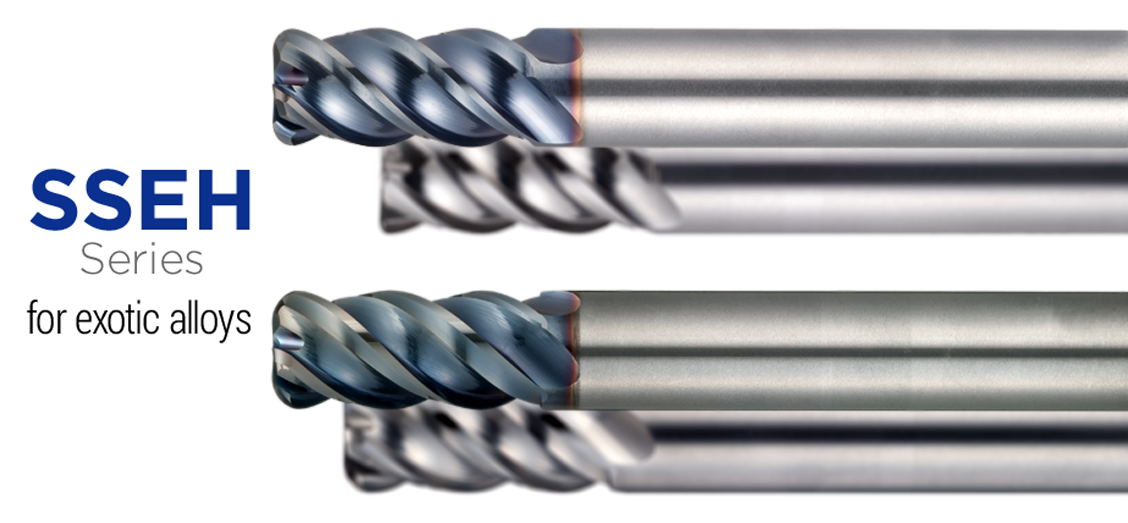

Radius endmill for exotic alloys

Radius endmill for exotic alloys- M

- S

SSEH seriesMore Detail