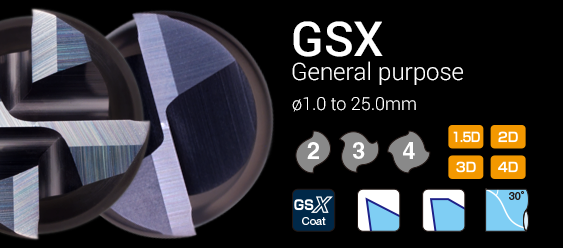

GSX Mill series

New generation, global standard cemented carbide endmill

Work Material

- P

- M

- K

- S

- H

Feature

New generation, global standard cemented carbide endmill

Utilizing a fine-grained carbide substrate with excellent toughness and thermal shock resistance for improved reliability in Wet machining.

Utilizing the high wear and thermal resistant GSX Coat, for improved reliability and long tool life in a wide range of work materials.

Expanded machining applications with 2 types of cutting edge profiles

Lineup includes sharpness-centered S type (sharp corner edge) and fracture resistant-centred C type (strengthened edge: with gash land).

Improved chip evacuation ability

Large rake angle combined with an unique flute profile helped improve sharpness and chip evacuation ability.

High precision

By suppressing variations, outer diameter tolerance is reduced by 2/3 as compared to conventional, diameter adjustment is not required when replacing the tool.

High rigidity, long cutting edge length

Improved surface accuracy with high rigidity, long cutting edge length (4D) type.

Drastic improvement on chattering and fracture resistance

Optimum irregular pitch + irregular lead drastically improve chattering and fracture resistance to achieve high speed, high feed milling with low cutting force.

Huge improvement in surface quality

Adopting a round land drastically improved machining surface quality. (Adopted a round land of ø5mm or more.)

GSX Anti-vibration Type Regrinding Instructions

Download PDF

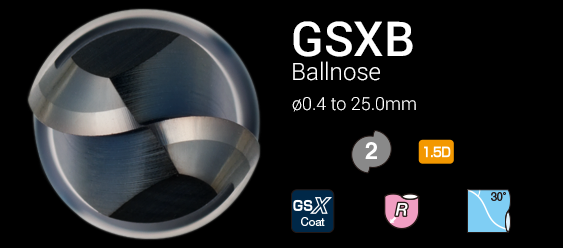

Improved thermal and wear resistance

Ultra fine-grained carbide substrate coupled with a new coating improves thermal and wear resistance.

Lowers cutting force

Lowers cutting force with strong helix angled R cutting edge.

Improved chip evacuation ability

Improved chip evacuation ability with a unique pocket shape + widened pocket area.

Multi-purpose

3-fluted slot endmill (1.5D) optimizes the flute profile to reduce cutting force.

1. Able to perform continuous (combination) machining including plunging and slotting.

2. Best suited for thin-walled machining and use with small machining center.

Product Inquiry

Feel free to contact us for cutting and machining information

on cutting troubles and review of tooling as well as questions,

feedbacks, and requests for our home page.

Recommend

-

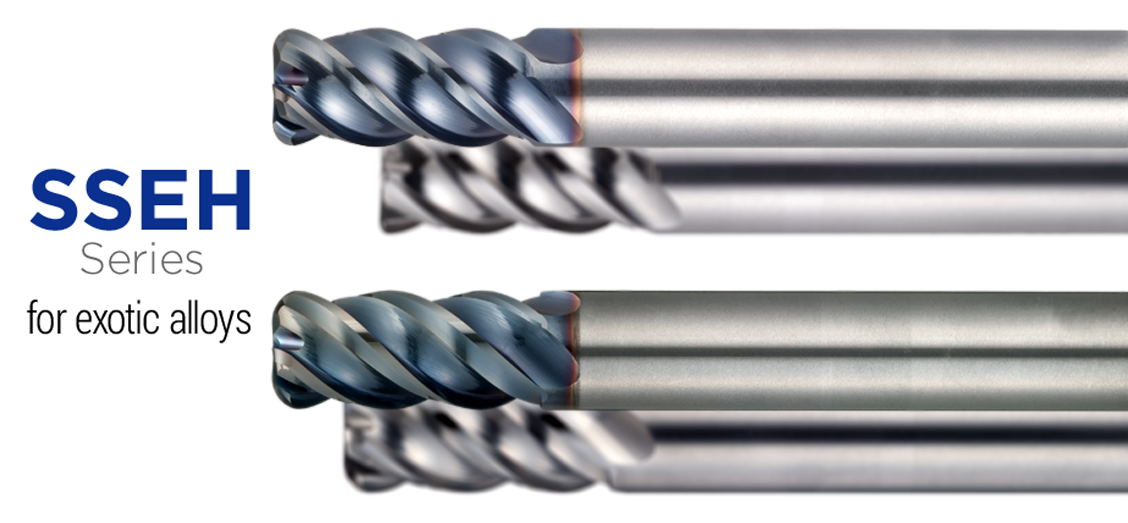

Radius endmill for exotic alloys

Radius endmill for exotic alloys- M

- S

SSEH seriesMore Detail -

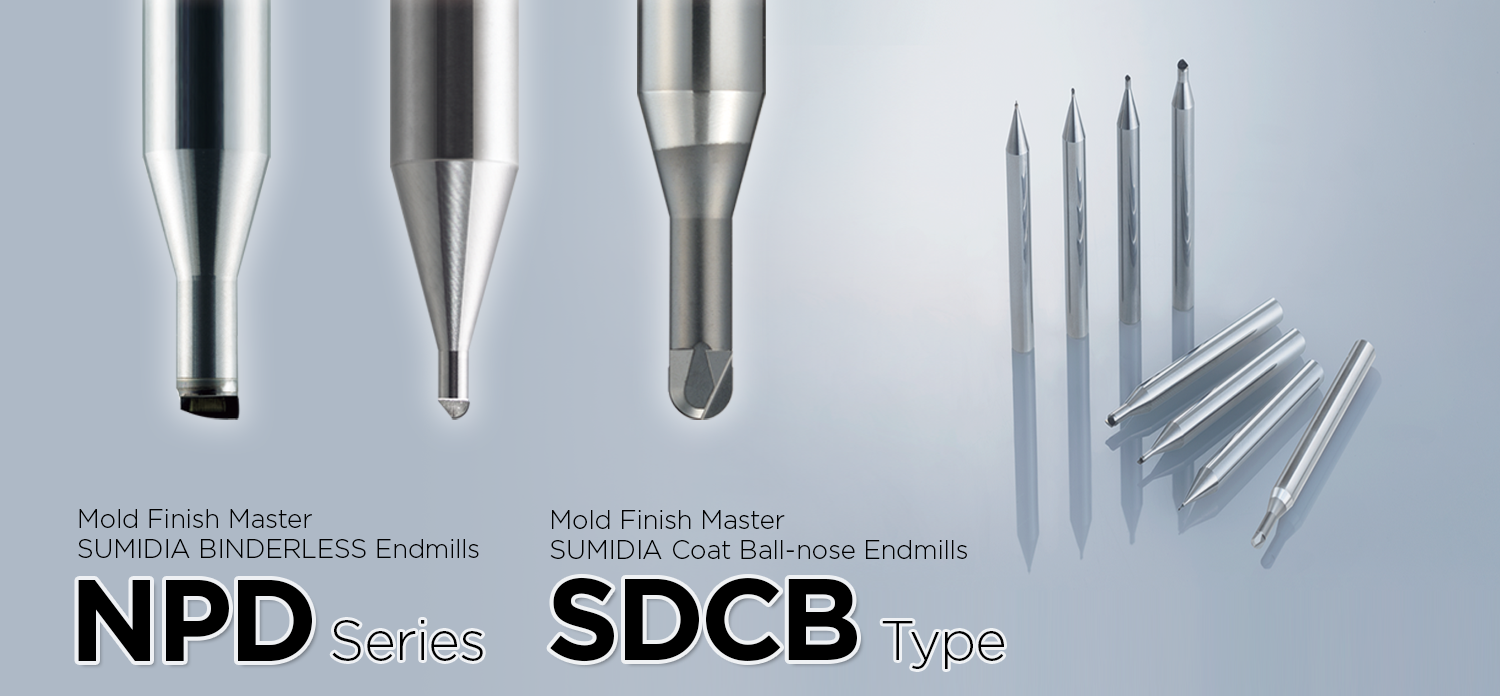

Direct milling on cemented carbide materials

Direct milling on cemented carbide materials- CC

- HB

SUMIDIA BINDERLESS Endmills NPD seriesMore Detail -

Small Diameter CBN Endmills for Hardened Steel

Small Diameter CBN Endmills for Hardened Steel- H

Mold Finish Master SUMIBORON BNBR series / BNBP seriesMore Detail