Grades Selection

Grades Selection (Milling)

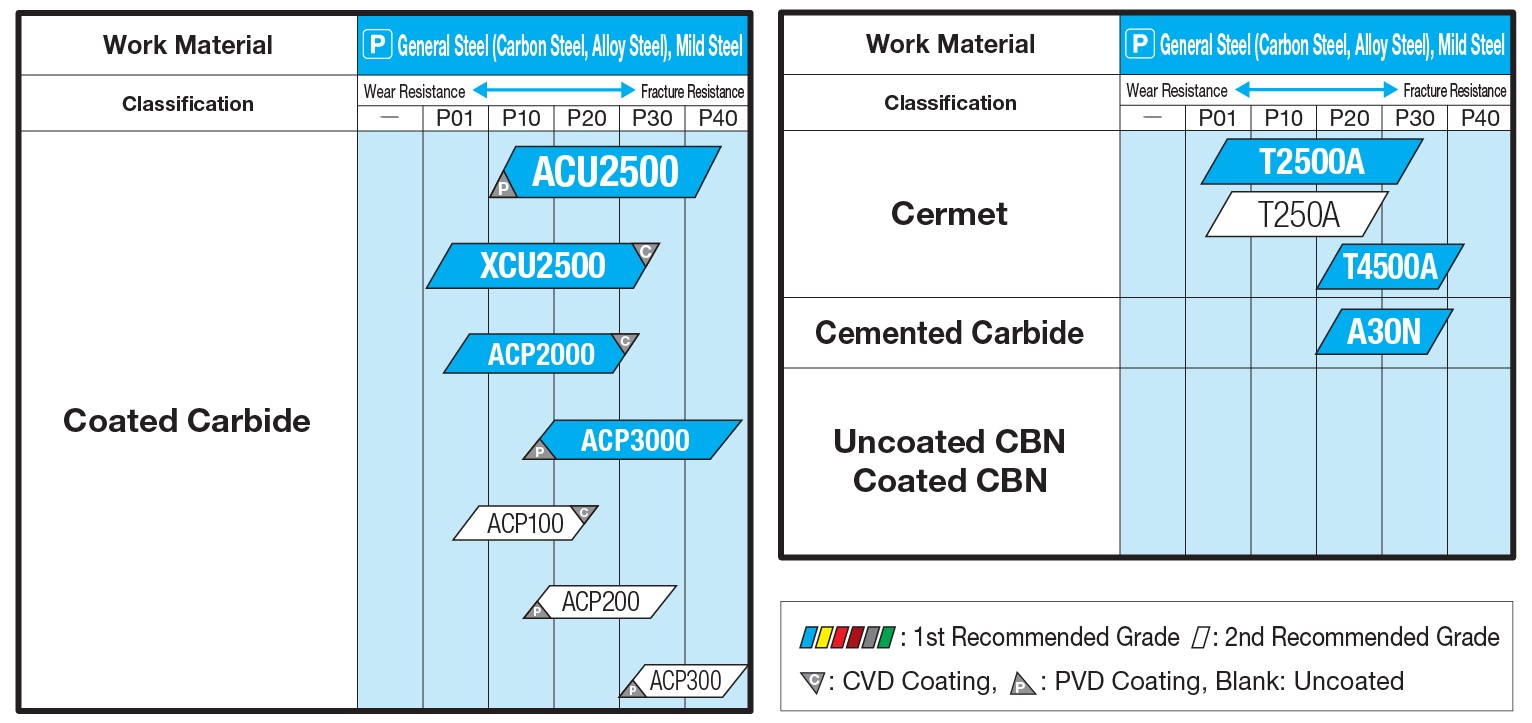

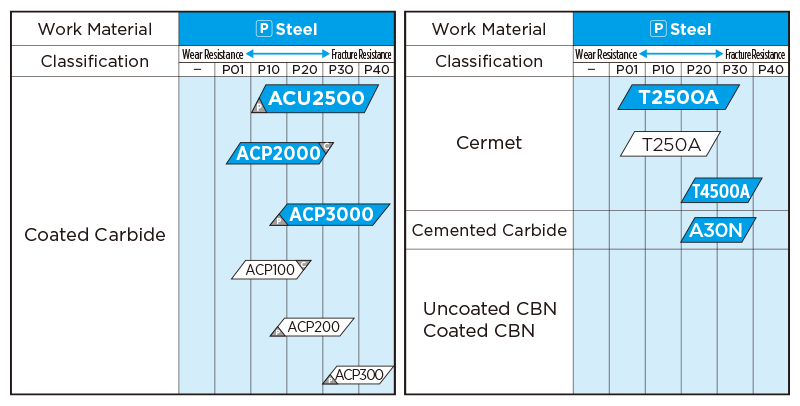

General Steel , Soft Steel P

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life on various work materials

ACP2000

For high-speed machining of steel

Stable long tool life in high-speed machining is realised by adopting a tough carbide substrate and a new coating with excellent thermal crack resistance

ACP3000

Our 1st recommended grade for milling steel

Carbide substrate with excellent thermal crack resistance, plus a new coating with excellent wear resistance and chipping resistance, realises stable long tool life over a wide range of cutting conditions

Cermet

T2500A

For finishing of steel and stainless steel

Fine, uniform grain structure greatly improves toughness, realising long tool life and excellent surface finishes

T4500A

For finishing of steel and stainless steel

Tough grade with excellent fracture resistance and reduced thermal cracking

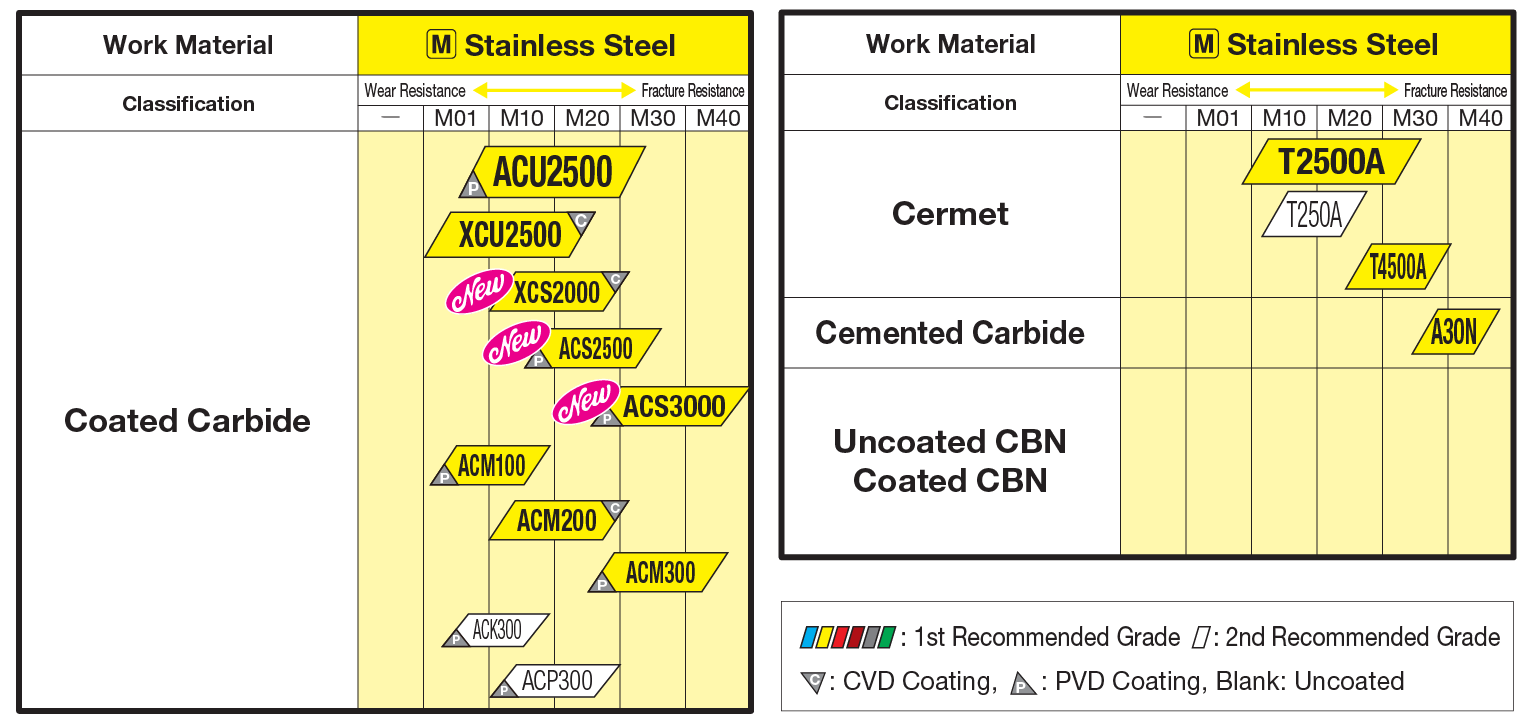

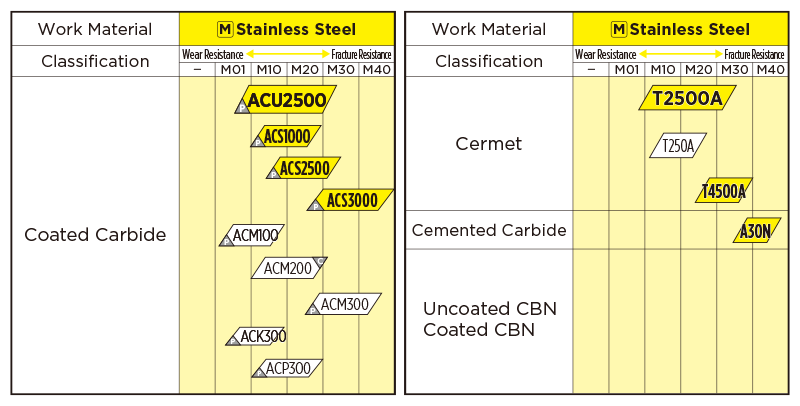

Stainless Steel M

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life on various work materials

ACS1000/ACS2500/ACS3000

ACS1000

For high-efficiency milling of exotic alloys

High-hardness carbide substrate coupled with a chipping-resistant coating provides long and stable tool life in high-speed, high-efficiency machining applications

ACS2500

First recommendation for titanium alloy applications

Carbide substrate with excellent wear and adhesion resistance, coupled with a chipping-resistant coating, balances excellent wear and fracture resistance

ACS3000

Suitable for a wide range of exotic alloy machining applications

Realises superb stability due to a high-toughness carbide substrate with a highly chipping-resistant coating

Cermet

T2500A

For finishing of steel and stainless steel Fine, uniform grain structure greatly improves toughness, realising long tool life and excellent surface finishe

T4500A

For finishing of steel and stainless steel Tough grade with excellent fracture resistance and reduced thermal cracking

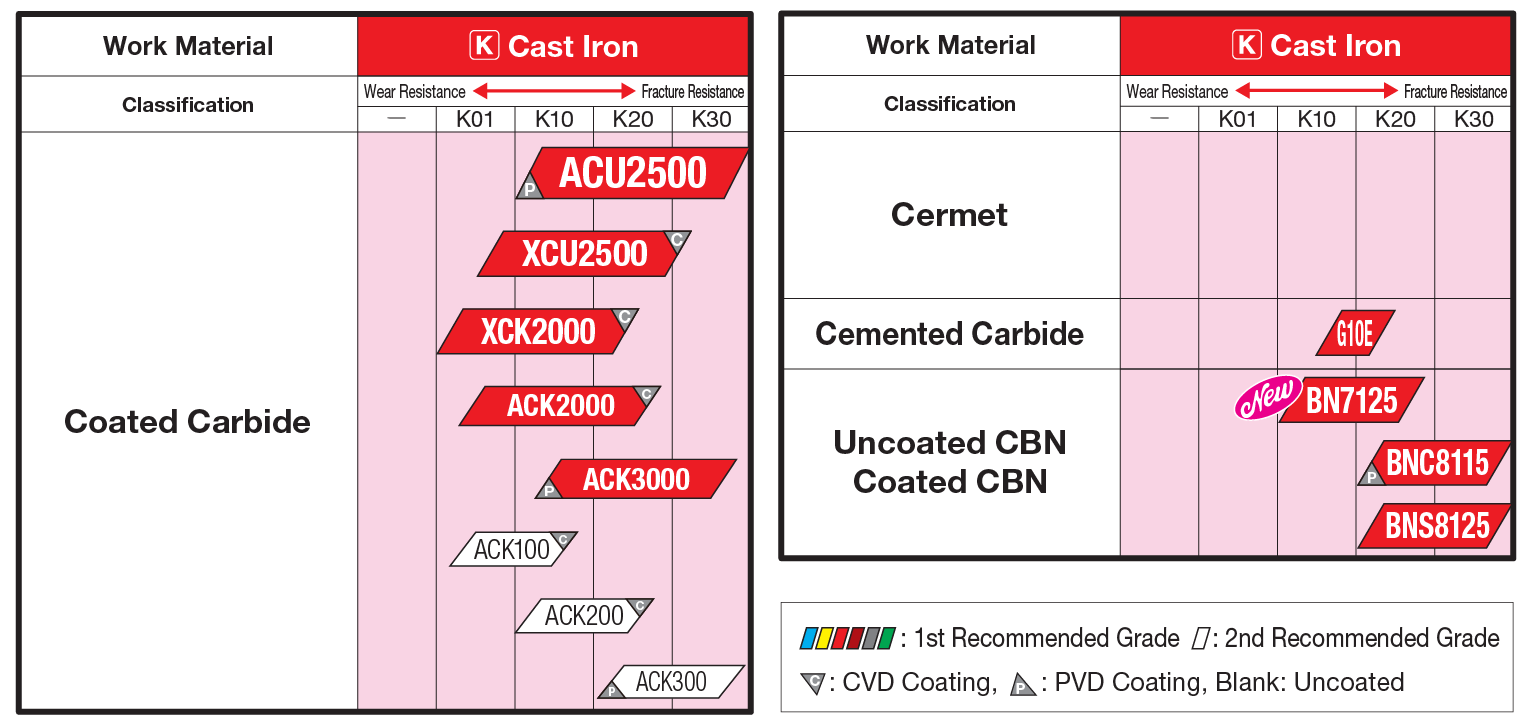

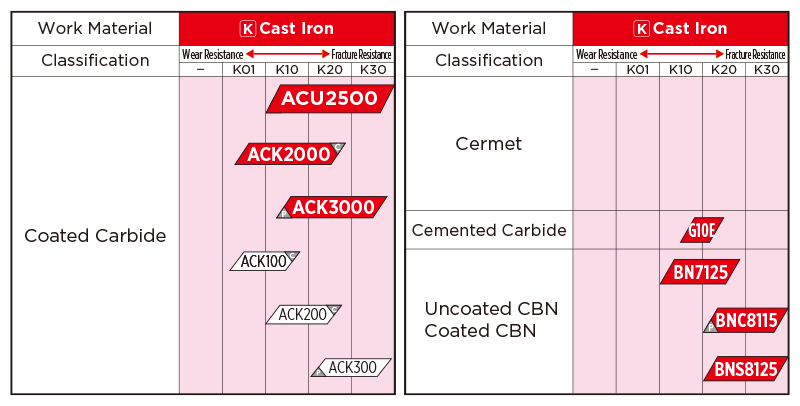

Cast Iron K

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life on various work materials

ACK2000

For high-speed cast iron milling

Stable long tool life with high-speed machining is realised by adopting a tough carbide substrate and a new coating with excellent thermal resistance

ACK3000

Our 1st recommended grade for milling cast iron

Adopts a high thermal conductivity carbide substrate and a new coating with excellent wear resistance and chipping resistance, realizing stable long tool life over a wide range of cast iron machining operations

Uncoated CBN

Coated CBN

BN7125

General-purpose grade with excellent wear resistance, fracture resistance, and thermal shock resistance, suitable for machining of cast iron and exotic alloys

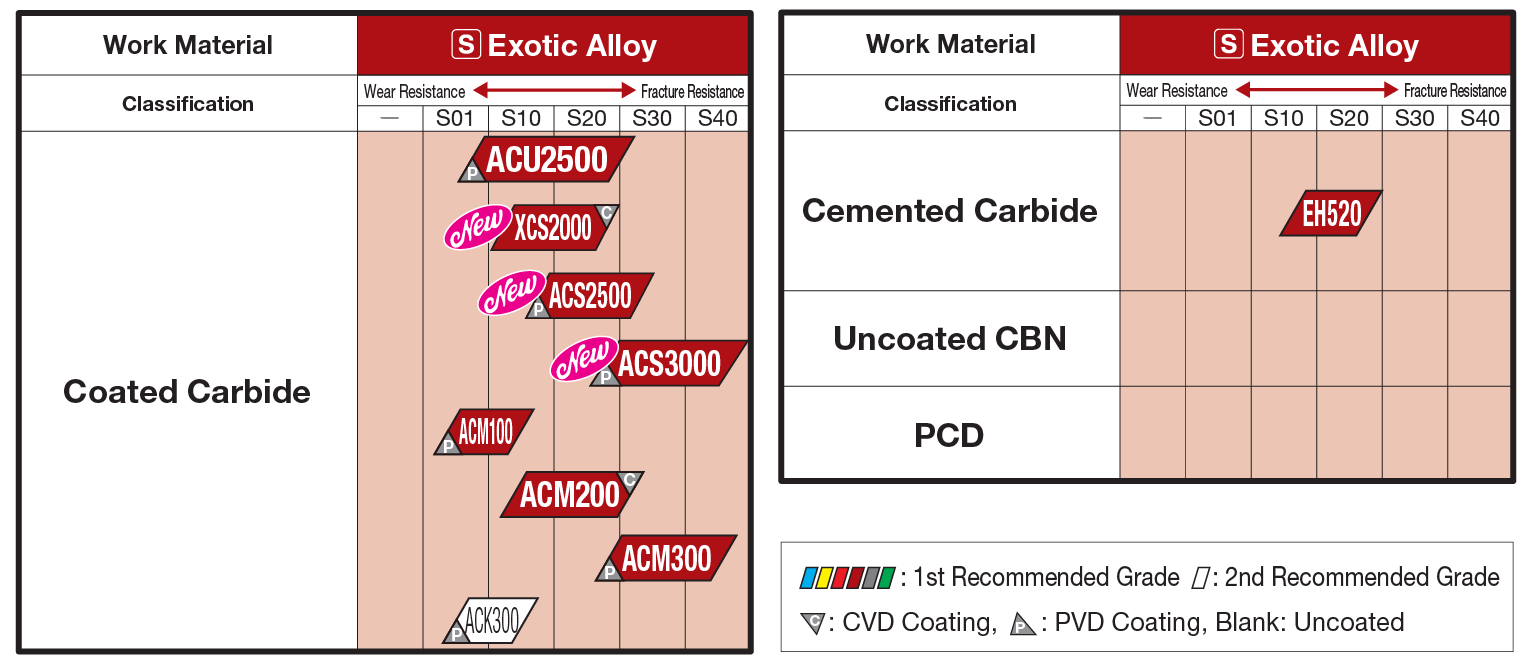

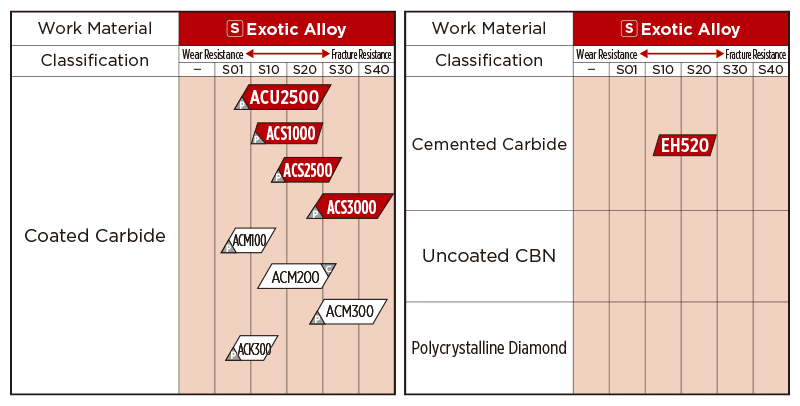

Exotic Alloy S

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life with various work material grades

ACS1000/ACS2500/ACS3000

ACS1000

For high-efficiency milling of exotic alloys

High-hardness carbide substrate coupled with a chipping-resistant coating provides long and stable tool life in high-speed, high-efficiency machining applications

ACS2500

First recommendation for titanium alloy applications

Carbide substrate with excellent wear and adhesion resistance, coupled with a chipping-resistant coating, balances excellent wear and fracture resistance

ACS3000

Suitable for a wide range of exotic alloy machining applications

Realises superb stability due to a high-toughness carbide substrate with a highly chipping-resistant coating

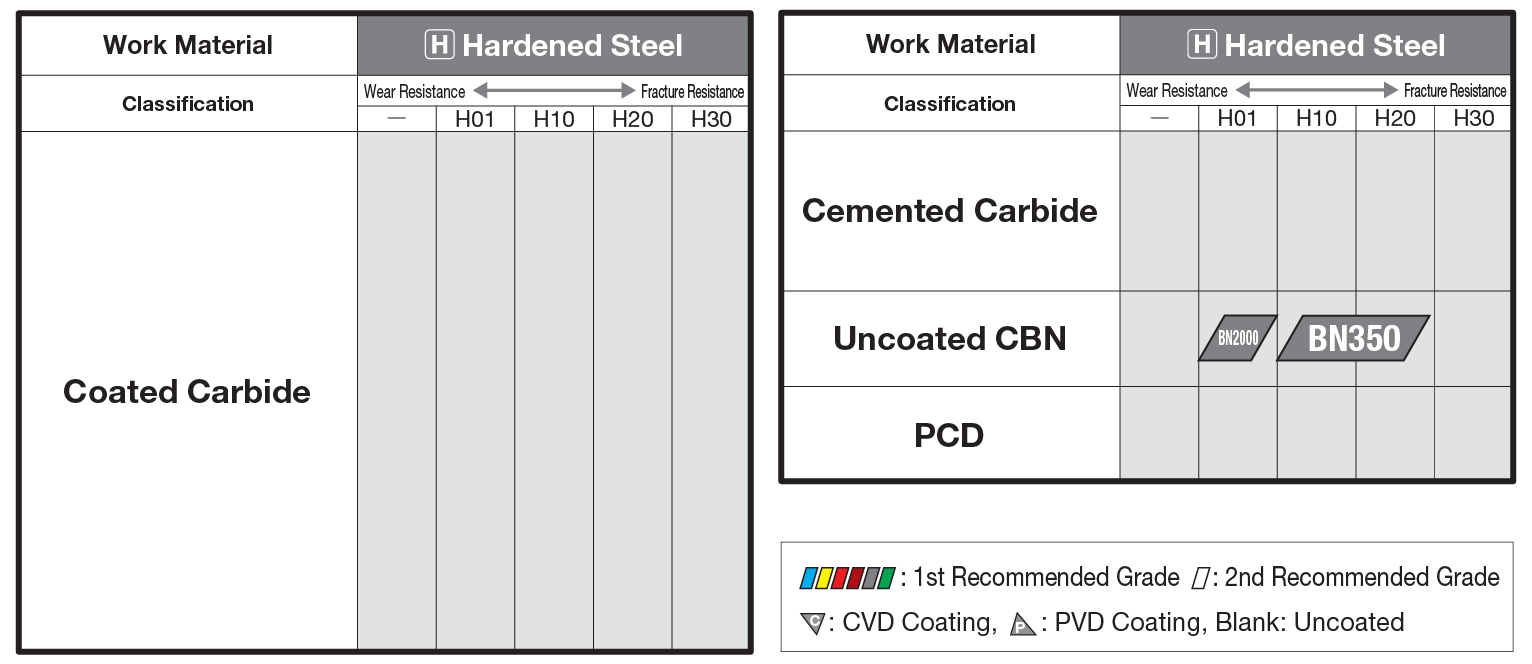

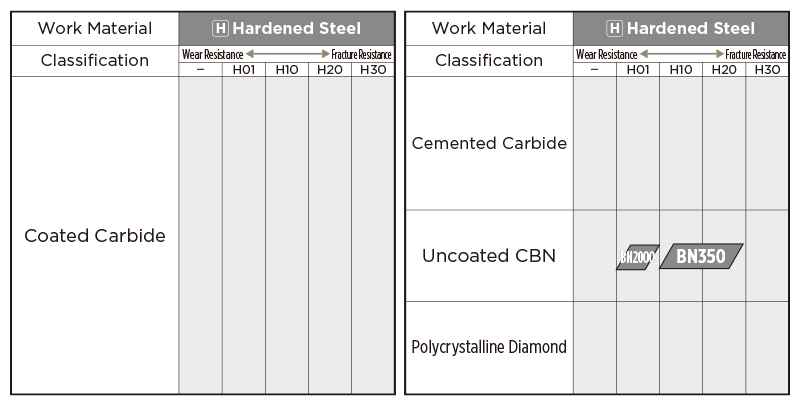

Hardened steel H

CBN (SUMIBORON)

BN350

Grade with ultimate cutting edge strength, suitable for heavy interrupted cutting

BN2000

General-purpose grade for general hardened steel machining with a high degree of fracture and wear resistance.

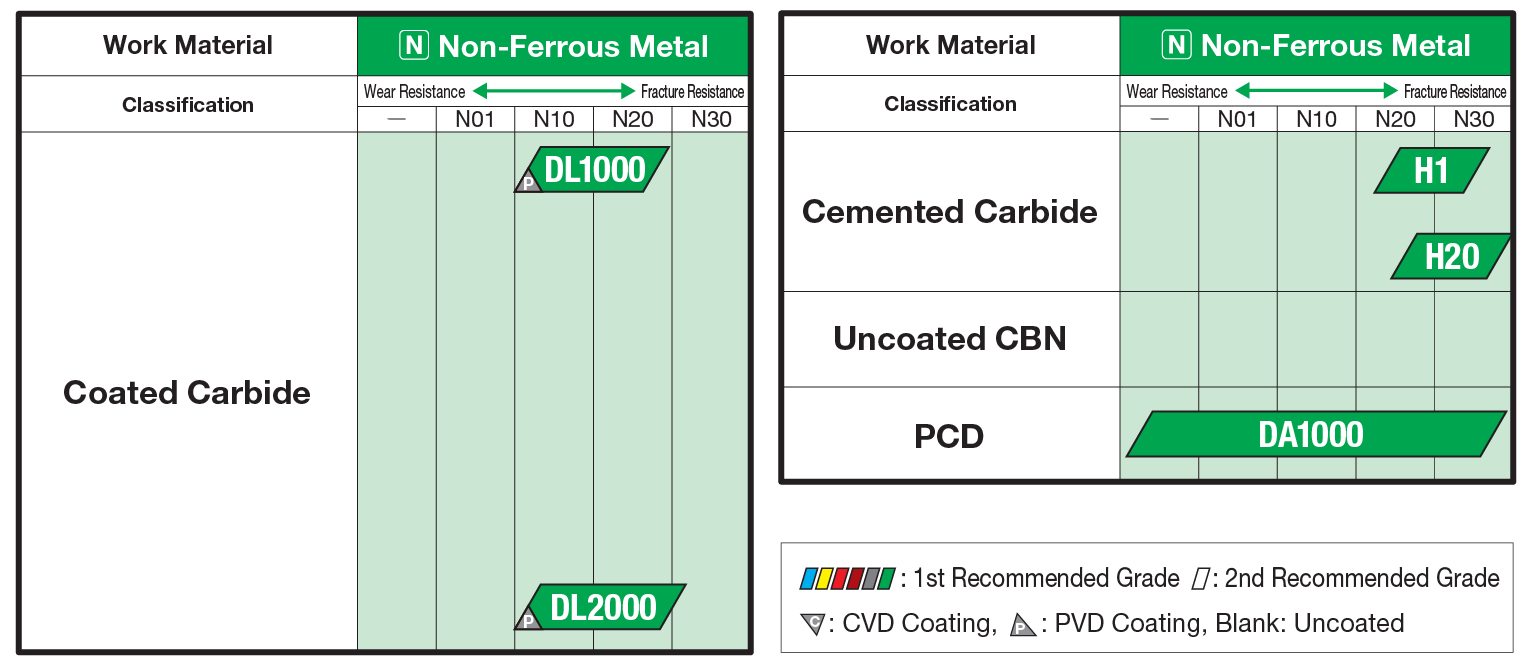

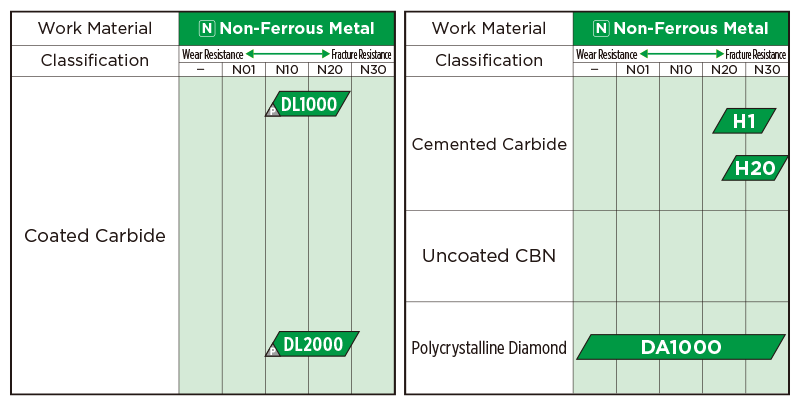

Non-Ferrous Metal N

Coated Carbide

DL1000/DL2000

For milling non-ferrous metal, utilising DLC coat with a low coefficient of friction and excellent adhesion resistance

PCD

DA1000

High-density sintered material made of ultra-fine grain diamond that demonstrates optimum wear and fracture resistance and excellent edge sharpness